Surface Magnetic Field refers to the magnetic flux density measured at a specific point on the surface of a magnet. It is expressed in units of Gauss (Gs) or Tesla (T), where 1 T = 10,000 Gs.

Because the magnetic field strength varies across different areas of a magnet’s surface, the value commonly referred to as the “surface magnetic field” usually represents the magnetic flux density at the center of the working surface of the magnet.

Measuring Surface Magnetic Field

The surface magnetic field is one of the easiest magnet performance parameters to measure in daily practice. It can be directly measured with a Gauss meter (also known as a Tesla meter), making the process very convenient.

When the shape and dimensions of magnets are the same, comparing surface magnetic field readings can provide a rough indication of their relative performance—particularly when the magnets are not multipole magnetized. For magnets that are very large, very small, or have complex geometries, measuring the total magnetic flux is more difficult, so measuring surface magnetic field becomes especially useful.

However, it’s important to note that readings may vary slightly between Gauss meters from different manufacturers because they use different Hall-effect sensors. Moreover, measurement standards differ across countries, which can also lead to discrepancies.

Despite its convenience, surface magnetic field measurement is not an objective or comprehensive indicator of a magnet’s overall performance. Therefore, it is not recommended as a key criterion for product evaluation or trade specifications.

Relationship Between Surface Magnetic Field and Remanence

Remanence, also known as residual magnetic flux density (symbol Br), refers to the magnetic induction that remains in a ferromagnetic material after it has been magnetized to saturation by an external magnetic field and the field is subsequently reduced to zero. It is measured in Tesla (T) or Gauss (Gs).

Remanence is an intrinsic property of the magnet and remains constant for a given magnet under specific conditions. While remanence influences the surface magnetic field, the two are not identical. Magnets with the same remanence value may still exhibit different surface magnetic fields due to variations in shape, size, and magnetization method. For magnets that are identical in shape and dimensions, a higher remanence will generally result in a higher surface field. However, for magnets with different geometries or sizes, surface magnetic field cannot be used as a direct indicator of remanence.

It’s also important to note that remanence is measured under a closed magnetic circuit, whereas surface magnetic field is measured in an open-circuit condition using a Gauss meter. Because a magnet naturally produces a demagnetizing field, the maximum surface magnetic field of a single magnet is much lower than its remanence.

For example, the maximum remanence of sintered NdFeB magnets is typically around 14,000 Gs, which means that the surface magnetic field of a single NdFeB magnet can never exceed 14,000 Gs. (This applies only to individual magnets—magnetic assemblies or arrays can achieve higher surface fields through special magnetic circuit designs.)

Calculating the Surface Field of NdFeB Magnets

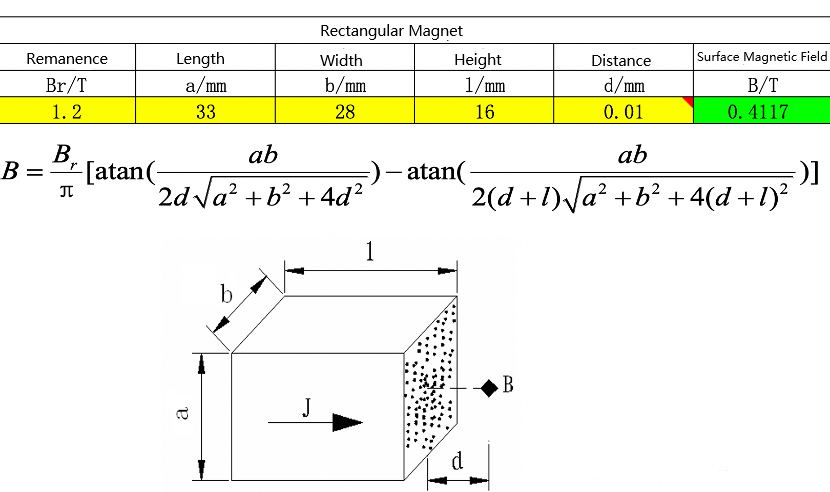

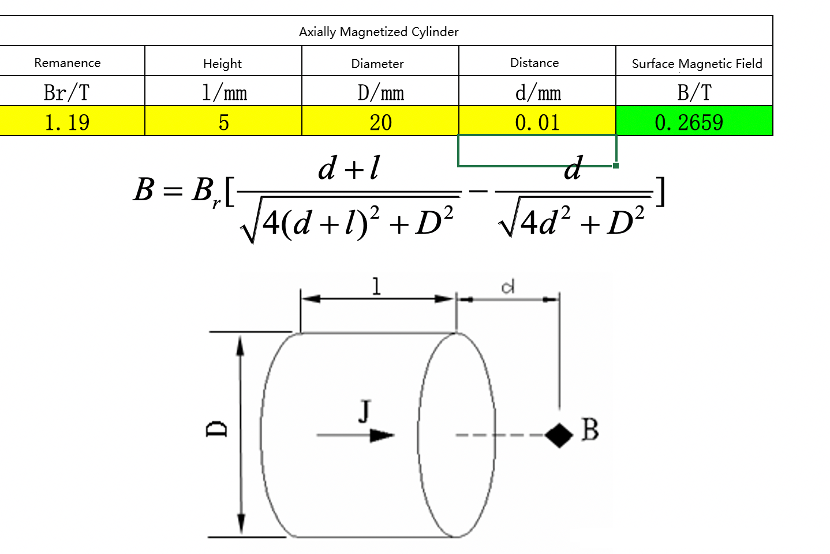

Sintered NdFeB magnets exhibit a very high magnetocrystalline anisotropy, so the magnetization vector aligns along the easy axis. In engineering practice, this allows us to approximate an NdFeB piece as a uniformly magnetized body. Under this approximation, many calculators and papers use the current-sheet (Amperian surface current) model to derive closed-form expressions for the magnetic field in space, including the surface magnetic field.

However, these formulas rest on two key assumptions:

- Uniform magnetization throughout the magnet’s volume.

- A perfectly linear demagnetization curve (straight B–H or M–H line) in the working range.

Real magnets rarely satisfy both perfectly. Microstructural variations, local demagnetizing effects, and slight nonlinearity of the recoil curve introduce deviations. As a result, calculated surface field values often differ from actual Gauss-meter measurements.

Beyond remanence (Br), the surface field depends strongly on geometry:

- Shape (block, cylinder, ring, arc, multipole segment, etc.)

- Dimensions (thickness along the magnetization axis vs. lateral size)

- Magnetization mode (axial, diametric, radial, or multipole)

Because geometry changes the internal demagnetizing factor and field distribution, different shapes require different formulas. In short, theoretical models provide useful estimates and comparisons, but final values should be verified experimentally for the specific magnet shape, size, and magnetization you’re using.