Hello and welcome to EPI Magnets. As a leading company in the magnet industry, we want to ensure that our customers and readers alike have a comprehensive understanding of key magnetic parameters. In this article, we will delve into the intriguing concepts of Surface Field and Magnetic Flux.

Surface Field

Surface Field, at its simplest, is the magnetic induction strength at the surface of a magnet. It’s defined as the magnetic flux passing through a unit area, hence it’s also known as the surface magnetic flux density. This parameter can be measured using instruments like a Gauss meter or other testing devices equipped with a Hall-effect sensor.

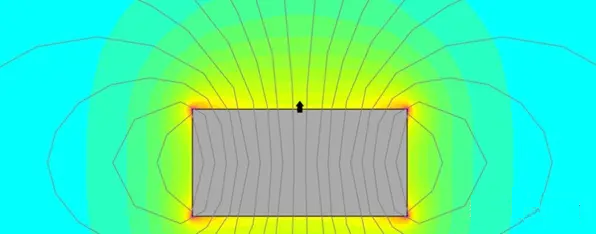

The surface field is not constant across the magnet due to its magnetic field distribution, which means that the surface field can vary depending on the specific point of measurement on the magnet. For applications that require a spatial magnetic field, the surface field, or the magnetic induction intensity value at a specified point, becomes an essential technical requirement.

The surface field of a magnet is intricately linked to its Length / Diameter (L/D) ratio, which is the ratio of the magnet’s length (or thickness, understood as the magnetization direction by default) to its diameter. This means, under the premise that the magnet’s length denotes its direction of magnetization, a larger L/D ratio results in a higher surface field. In other words, when the dimension along the magnetization direction is larger, the surface field tends to be higher. Additionally, it’s important to note that the measurements of surface field can vary slightly due to differences in the Hall elements used in Gauss meters from different manufacturers.

Magnetic Flux (Φ)

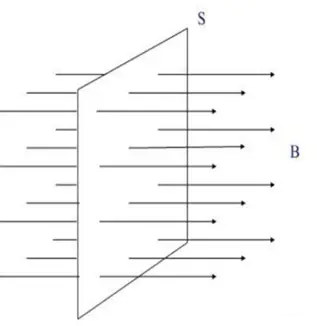

In physics, magnetic flux is defined as the quantity of magnetic force lines perpendicular to a certain area. Simply, it measures the overall magnetic size, with units in Weber (Wb). Represented by Φ, it’s calculated as Φ=B×S, where B represents magnetic induction intensity and S signifies the pole area. Therefore, the size of magnetic flux depends on both the pole area and magnetic induction intensity.

When the magnet is in an open-circuit state, the intrinsic flux density Bdi at the working point can be calculated using the method of converting magnetic flux to magnetic moment, where Bdi=Φ*K (coil constant)/V (magnet volume).

Residual Magnetism, Surface Field, and Magnetic Flux – Clarifying Confusions

- Residual Magnetism is the inherent property of the material, which remains constant for a piece of magnet under the precondition that there is no self-demagnetization. It is determined by the raw material formula and preparation process and is tested in a completely closed circuit state.

- The Surface Field is the magnetic induction intensity value at the measurement location (a small area) when the magnet or magnetic assembly is in an open or semi-open state. It’s crucial to remember that surface field is a vector with a specific direction, leading to significant data differences across various surfaces of the magnet. Typically, we refer to the surface field value that is perpendicular to the magnetic pole face. For a single magnet, the highest possible surface field is half of its remanence. However, in certain magnetic assemblies and magnet arrays, through a unique magnetic circuit design, it’s possible to enhance the surface field of the magnet, sometimes even exceeding its remanence.

- Magnetic Flux measures the overall magnetic size of a magnet tested through a coil. Typically, it is not suitable for measuring magnetic assemblies. Importantly, magnetic flux also has a default direction requirement. In actual measurements, a three-dimensional Helmholtz coil can be used to measure its total magnetic flux. When measuring both the surface field and the magnetic flux, special attention must be paid to the direction of testing.

Extra Knowledge - Magnetic Circuit

A magnetic circuit consists of one or more permanent magnets and magnetic materials arranged in a certain shape and size to form a component with a specific working air gap magnetic field. Magnetic materials in the magnetic circuit control the direction of magnetic flux, increase local magnetic induction intensity, prevent or reduce magnetic leakage, and enhance the mechanical strength of the entire component.

Understanding these key parameters and concepts are essential for any application involving magnetic materials. Stay tuned to EPI Magnets for more insightful and interesting articles about the magnet industry!

Remember to share this article and visit our website for more exciting information about the world of Magnetics! Stay Magnetic!