In the intricate world of magnet production and distribution, the packaging and transportation phase holds paramount importance. Given that the magnets possess a strong magnetic force, proper packaging is imperative to prevent any potential adverse effects on the surrounding environment and other equipment. In this article, we delve into the conventional packaging process that adeptly utilizes demagnetizing packaging, effectively altering the magnetic field distribution of the magnets without eliminating their magnetic properties, akin to a Faraday cage offering magnetic shielding.

White Box Packaging (small white boxes)

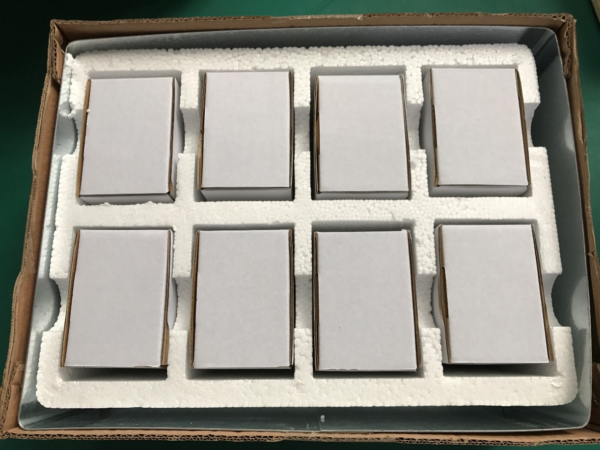

Magnet deliveries are usually undertaken post magnetization, a process where their formidable magnetic properties become more pronounced. Typically, magnets of standard dimensions are housed in white boxes, known colloquially in the industry as ‘small white boxes’. The first step involves wrapping the magnets securely in transparent plastic bags, ensuring that no space remains within the box which could allow the magnets to shift during transportation. Details such as the dimensions and quantity of the magnets are clearly marked on each box (Fig. 3).

Securing the Package

Once secured in the small white boxes, they are then placed in high-density cardboard boxes, with ample foam filler to cushion the contents during the shipping process. This exterior box is clearly labelled with details that inform the customers about the product quantity contained within each package (Fig. 4).

Magnetic Shielding with Iron Sheets

A vital aspect of this packaging strategy is the use of iron sheets to modify the magnetic field distribution surrounding the packaged magnets. This step involves surrounding the bottom and the sides of the cardboard box with iron sheets to create a magnetic shield reminiscent of a Faraday cage. This safeguard ensures the magnetic forces are contained within the packaging, thereby preventing any external disturbances (Fig. 5). For further insights on magnetic shield packaging, we invite you to explore our detailed article: How to Meet the Air Transport Standards for Shipping Magnets.

Final Preparations

The final step in this meticulous process sees the application of strapping bands to firmly secure the cardboard boxes, which are then mounted onto pallets for easier transportation and handling, ensuring the safety of the product till it reaches its destination (Fig. 6 & Fig. 7).

Packaging Non-Conventional Magnet Sizes

When it comes to larger or non-standard magnet sizes and assemblies, the packaging process can be quite intricate. Sometimes, the usage of cardboard boxes might not be viable. In such instances, customized packaging solutions are crafted based on the specific requirements, ensuring optimal protection and convenience.