The transportation of magnetic materials through air presents unique challenges owing to the potential interference they can cause with an aircraft’s navigation system and control signals. Recognizing these challenges, the International Air Transport Association (IATA) classifies magnetic materials as class 9 hazardous goods, imposing specific regulations and guidelines to maintain safety standards during air transit. This article guides you through meeting these standards, ensuring your magnetic shipments remain compliant.

Understanding the Regulatory Landscape

The IATA has laid down two critical rules to govern the air transportation of packages containing magnets:

- Rule #1: Any package shipped by air must exhibit a field strength of 5.25 milligauss or less at a distance of 15 feet from the surface of the package, as per FAA Title 49, Part 173.21. A package exceeding this limit is not suitable for air shipping.

- Rule #2: If the field strength at a distance of 7 feet from the package is 5.25 milligauss or higher, it must be labeled as “Magnetic”, a rule particularly pertinent to international shipments.

Adopting the Right Packaging Strategy

To adhere to the above regulations, magnetic shielding measures must be implemented. A specialized shielding packaging that includes foam boards and magnetic shielding plates is utilized to meet the air safety transport requirements.

Shielding Materials and Packaging Designs

- Materials: High magnetic permeability materials such as cold-rolled plates or galvanized plates are often used to create shielding plates. Depending on the volume of magnetic materials, several layers of these plates might be needed.

- Packaging Design: The magnet is placed in an eight-hole foam box, specifically designed for export purposes (as illustrated in Fig. 1). For larger magnets, additional shielding layers and larger packaging options like wooden boxes might be necessary.

- Magnetic Field Circulation: Utilizing the principle of the Faraday cage, the magnetic field mainly circulates within the box, significantly reducing leakage.

Ensuring Compliance through Magnetic Field Strength Measurement

In the field of magnet transportation, maintaining compliance with international shipping regulations is of paramount importance. As a professional magnet supplier, we emphasize that, before any shipment is dispatched, we conduct rigorous inspections and measurements using a magnetometer to ensure that all regulatory standards are met. Our commitment to safety and compliance safeguards the integrity of the navigational systems of aircraft and prevents any potential disturbances during flight.

For our readers, especially those who might not have access to a highly sensitive magnetometer but need to ship goods containing magnetic materials, we would like to offer a piece of valuable advice. In such cases, you can utilize a compass for a preliminary evaluation of the magnetic field strength around the packaging. Through extensive tests conducted on several large-sized magnets, we have developed an effective method to estimate the magnetic field strength using a compass.

Guideline for Compass Measurements:

Rule 1: If the compass indicates a deviation of about 15 degrees at approximately 32 inches from the magnet, which represents a field strength greater than 2 milligauss at 7 feet, your package might be classified as a magnetic hazard, unsuitable for air transportation.

Rule 2: Similarly, a deviation near 15 degrees at a distance of 7 feet from the package suggests a field strength exceeding 5.25 milligauss at 15 feet, making it unfit for air transport. In this scenario, consider lining the inside of the packaging box with steel plates to provide a shielding effect.

If you’re using a smartphone, both iPhone and Android have compass applications available that can substitute a traditional compass effectively. These apps can be an excellent alternative for measuring magnetic field strength.

Utilizing several magnets can drastically modify the detected magnetic field intensity.

Indeed, the majority of consignments are not merely a lone magnet situated in an open space.

The presence of additional magnets in close proximity can induce substantial alterations to the magnetic field.

In instances where numerous magnets are transported, they are frequently organized in staggered piles, with each pile’s magnetic poles oriented in contrasting directions. This arrangement not only facilitates a more cohesive and aesthetically pleasing stack but also diminishes the magnetic field intensity considerably at a farther distance.

Surprisingly, a configuration of two stacks of magnets with opposing polarities situated adjacent to each other can sometimes exhibit a reduced magnetic field intensity at a distance compared to a solitary magnet!

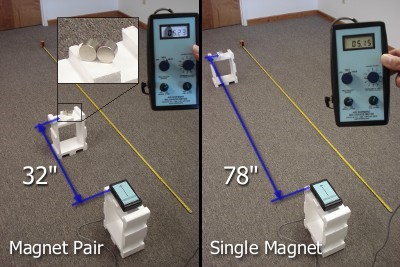

Refer to the Fig. 3 for an illustrative example of this phenomenon. A solitary DX8X0 magnet projects a magnetic field strength of 5.25 milligauss at a distance of 78 inches. Conversely, a duo arranged adjacently with their north poles facing divergent directions manifests a significantly attenuated magnetic field in its vicinity. To experience the same 5.25 milligauss intensity, one needs to approach within approximately 32 inches.

As a rule of thumb, the presence of other magnets or ferromagnetic entities in your consignment will diminish the magnetic field intensity observed at a specific distance. Should your magnet adhere to a steel surface, or is encased by steel or other ferromagnetic substances, the magnetic field intensity you measure is likely to be lesser.

On the left, a duo is aligned adjacently with their north poles directed in contrasting directions. On the right, a solitary DX8X0 is being gauged. At the demonstrated distance, the magnetic field intensity approximates 5.25 milligauss. In both scenarios, the magnetic field intensity falls below 5.25 milligauss at a span of 15 feet (180 inches), indicating that these magnets are eligible for air transportation.