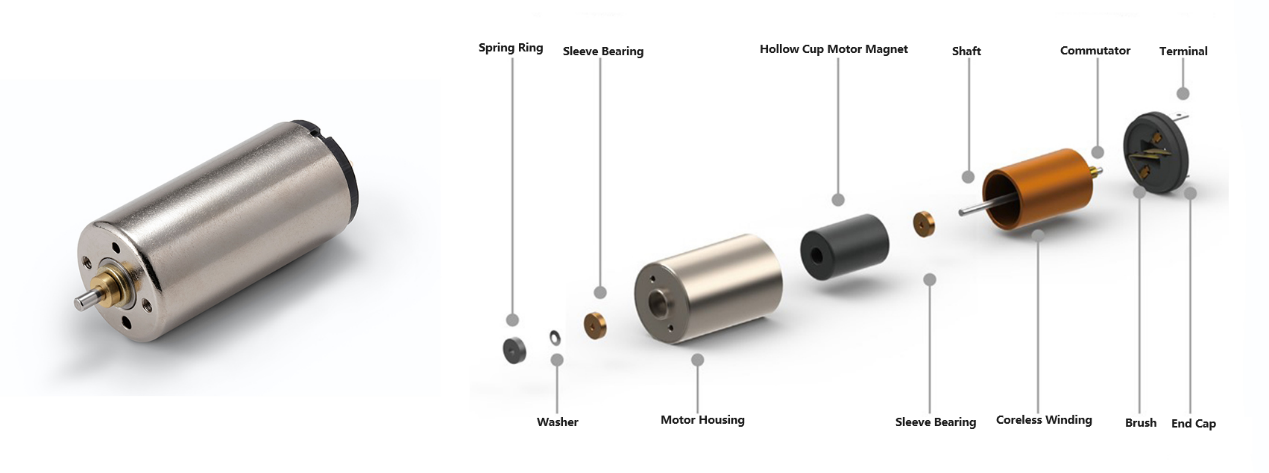

Hollow cup motors, also known as coreless or ironless motors, are at the forefront of micro-motor technology innovation. These motors differ significantly from conventional motors by utilizing slotless and coreless coils in their armature windings. This design innovation not only revolutionizes the traditional rotor structure but also substantially reduces the motor’s weight and rotational inertia. By eliminating the iron core, these motors drastically reduce the energy losses typically associated with eddy currents. Their low energy consumption, coupled with high sensitivity and superior performance, positions hollow cup motors as a pivotal development in the field of electromechanical engineering.

Advantages of Hollow Cup Motors

- Reduced Rotational Inertia: The coreless design minimizes inertia, allowing for rapid acceleration and deceleration, enhancing the motor’s responsiveness – a crucial factor in applications requiring precise motion control.

- Efficiency and Performance: Without magnetic resistance torque and eddy current losses, these motors operate with higher efficiency, translating to energy savings and prolonged battery life in portable applications.

- Exceptional Sensitivity: Their design allows for immediate response to control inputs, making them ideal for applications where precision is paramount.

- Power-to-Volume Ratio: These motors offer a higher power output relative to their size, making them suitable for compact, space-sensitive applications.

- Smooth Operation: The absence of cogging torque ensures a smoother operation with minimal noise, a desirable attribute in noise-sensitive environments.

- Communal Advantages: The low inductance and superior commutation reduce electrical noise, enhancing performance in electronically sensitive applications.

- Durability and Longevity: Enhanced heat dissipation capabilities ensure a longer lifespan, reducing maintenance costs and downtime.

Classification and Working Principle of Hollow Cup Motors

Hollow cup motors are classified into brushed and brushless types based on their commutation method. Brushed motors feature mechanical commutation with stationary magnetic poles and a rotating coil. The commutation process, facilitated by a rotating commutator and stationary brushes, periodically reverses the current direction in the coil. Brushless motors, in contrast, use electronic commutation, negating the need for physical brushes and commutators. This not only reduces maintenance but also extends the life of the motor.

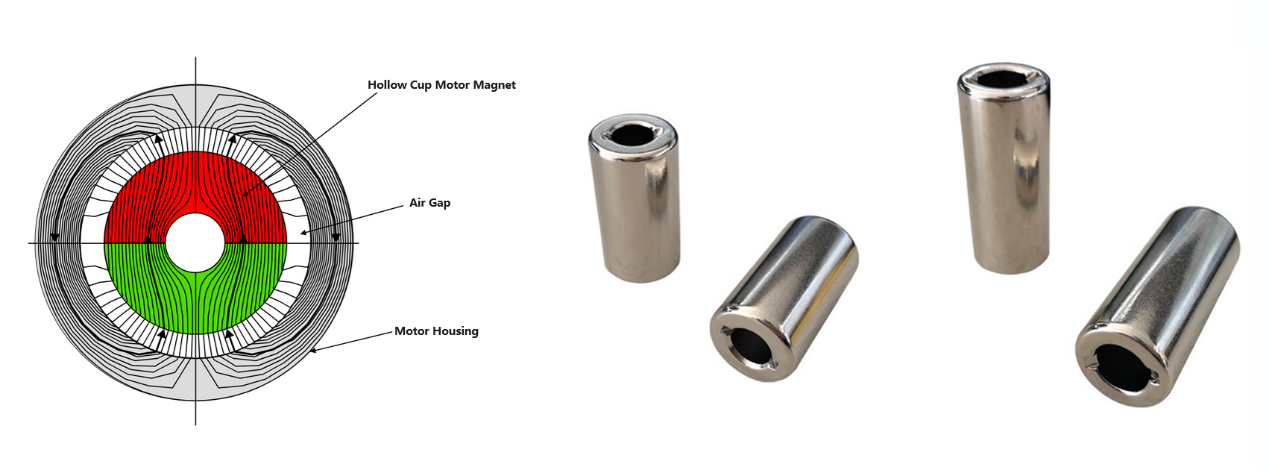

About Hollow Cup Motor Magnets

Most hollow cup motor magnets are crafted from high-performance sintered neodymium-iron-boron (NdFeB). The choice of NdFeB is due to its exceptional magnetic properties, which include a high coercivity and remanence. These properties are crucial in achieving the desired magnetic flux in a compact space. The unique radial magnetization of these magnets, along with the specialized slot design on the annular magnet end faces, is integral to achieving the motor’s operational efficiency. These design features optimize the magnetic field distribution, contributing to the motor’s overall performance.

Conclusion

The evolution of hollow cup motors and their specialized magnets represents a significant leap in micro-motor technology. With their compact size, efficient operation, and versatility, they are increasingly becoming the motor of choice in various applications, from consumer electronics to aerospace. As technology advances, we can anticipate even more innovative uses for these motors, driving the future of compact and efficient electromechanical systems.