In the realm of magnet technology, the Halbach Array stands as a beacon of innovation and efficiency. This unique magnetic structure, discovered and refined by American scholar Klaus Halbach in 1979, aims to maximize magnetic field strength using the minimum amount of magnets. Let’s delve deeper into the fascinating world of Halbach Arrays and explore their structure, applications, and manufacturing techniques.

Unveiling the Halbach Array: A Revolutionary Magnetic Structure

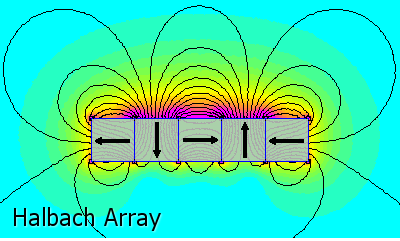

The Halbach Array, also known as the Halbach permanent magnet, emerged as a near-ideal structure in engineering, offering a remarkable way to enhance the field strength in a specific direction. Comprising entirely of rare earth permanent materials, this array utilizes a special arrangement of magnets with varying magnetization directions. This setup allows for the concentration of magnetic flux lines on one side of the array, while significantly weakening them on the other, creating an ideal unilateral magnetic field.

This magnetic structure has found extensive applications in various industrial sectors, including nuclear magnetic resonance, magnetic levitation, and specialized permanent magnet motors, thanks to its excellent magnetic field distribution characteristics.

Understanding the Magnetic Field Distribution

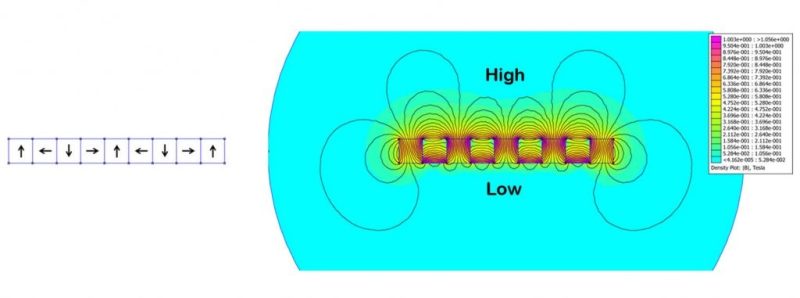

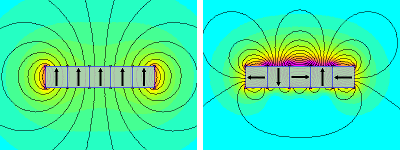

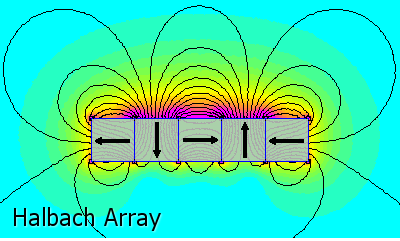

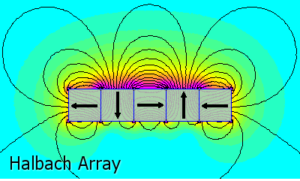

To fully comprehend the efficacy of the Halbach Array, it’s beneficial to visualize a comparison between a single magnet and a Halbach Array, as depicted in the accompanying images.

On the left, a single magnet is depicted, constituted of five identical magnet segments arranged in a column, akin to the structure of the Halbach array. However, in this case, all the north poles are pointing upwards. This configuration magnetically equates to a single elongated magnet, with the field strength being equally potent at both the top and the bottom, as indicated by the color scale in the image.

In stark contrast, the image on the right showcases a Halbach array, where the magnetic field is significantly intensified at the top while being considerably weaker at the bottom. This unique arrangement allows for a magnetic field strength on the top surface that is about 1.4 times (or √2 times) that of a traditional single magnet, especially noticeable when the magnetization direction thickness is between 4 to 16 mm.

This visual representation vividly illustrates the distinct advantages of Halbach arrays in optimizing magnetic field distribution, thereby elucidating why they are preferred in various applications necessitating enhanced magnetic field configurations.

Forms of Halbach Arrays

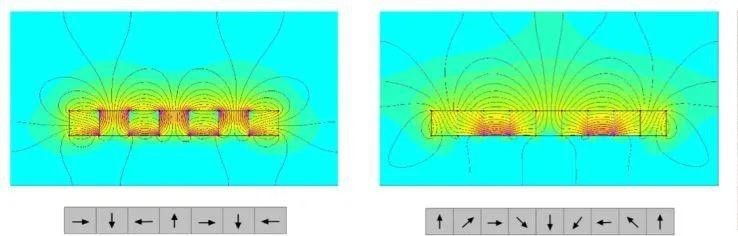

The Linear form represents the most fundamental structure of Halbach Arrays, combining radial and tangential arrays in a seamless manner.

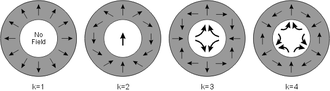

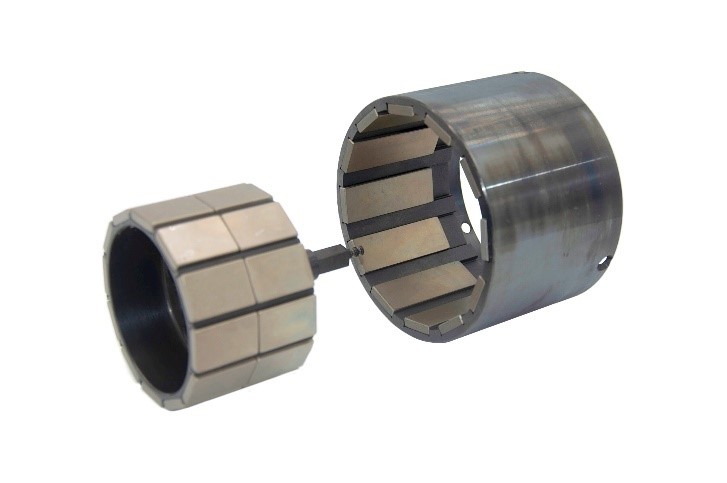

Circular Halbach Arrays are essentially linear arrays connected end-to-end to form a circular shape. These arrays facilitate a more sinusoidal distribution of the air gap magnetic field in permanent magnet motors compared to traditional ones, achieving higher air gap magnetic flux density and reduced iron losses with the same amount of permanent magnet material. Moreover, circular Halbach Arrays are widely used in permanent magnet bearings, magnetic refrigeration devices, and magnetic resonance equipment.

More details about Circular Halbach arrays, please refer to another article: Halbach Circles: Exploring the Magnetic Wonders of Circular Arrays

What's the purpose behind acquiring Halbach Arrays, and where can you find them in action?

Drawing inspiration from Wikipedia: The concept of one-sided flux distributions might appear somewhat theoretical at first glance, yet they find utilization in a vast array of applications, extending from commonplace refrigerator magnets to sophisticated industrial setups like Magnetic Rotor Assemblies and Magnetic Couplings. The brainchild of Klaus Halbach, these arrays were initially conceived to function as wiggler magnets in particle accelerators and free electron lasers.

Furthermore, Halbach arrays serve as a fundamental element in the Inductrack magnetic levitation train system. In this system, the arrays function to repel wire loops constituting the track, effectively lifting the train post-acceleration, facilitating a frictionless and efficient mode of transportation.

A Tip: Sometimes, a Halbach Array Isn't the Strongest Pull for You!

Halbach magnets often pique curiosity due to their unique and fascinating nature. The interaction between magnetic fields in these arrays is quite intriguing, leading many to assume that they offer the most potent magnetic configuration available.

However, if your primary concern is the pull force exerted by a magnet, a Halbach array might not be your optimal choice. For achieving the maximum pull force on a steel surface, there exist alternatives that offer greater strength. It’s essential to note that the primary purpose behind the invention of these arrays was to create a potent, alternating magnetic field on one side to guide electron beams, not to enhance adherence to steel surfaces!

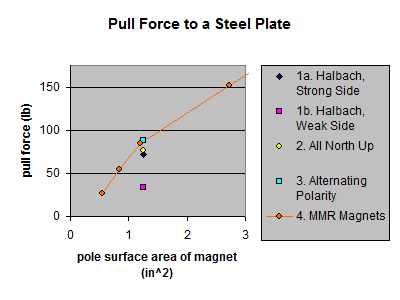

When we delve into the aspects of Pull Force and Field Strength, the comparison unfolds as follows:

- A Halbach array consisting of five ½” cubes (utilizing the same B888-2PA-N52 and B888-2PE-N52 magnets)

- “All North Up”: An cubes arrangement of five 1/2” cubes (B888-N52), all oriented with the north pole facing upwards (this behaves akin to a single large magnet)

- Alternating Polarity: A setup of five ½” cubes (B888-N52) with alternating polarities (the first magnet has the north pole facing upwards, followed by the second with the south pole upwards, and so on)

- A Mounting Magnet of comparable size, encompassing a single magnet surrounded by a steel cup or channel to redirect the magnetic field emanating from the magnet’s rear side (the MMR-A-Y8 magnet closely resembles the array under consideration)

The graph below illustrates the outcomes of our experimental analysis. We employed these four magnet configurations on our Pull Force, Case 1 testing apparatus, where the magnet(s) pull force was gauged against a large, flat steel surface.

The Halbach array exhibited a pull force of approximately 72 lb on its stronger side. Though formidable, an assembly of 5 magnets with their north poles all facing upwards demonstrated slightly superior strength, registering at 77 lb.

By orchestrating the magnets in a sequential north-south-north-south alignment, we observed a further enhancement in force, clocking in at 88 lb.

Based on the results of our pull force experiments, we can draw the following conclusion: If your primary focus is to maximize the pull force exerted by a magnet on a steel surface, the Halbach Array may not be the most economical option for you. Instead, the Mounting Magnet emerges as a more prudent choice. This specialized magnet employs a steel casing or cup to redirect the magnetic field from the rear of a single magnet, effectively doubling the pull force you would normally expect. In our tests, the MMR-A-Y8 magnet registered a pull force of 84 lb. With a similar footprint, this alternative not only delivers comparable or even greater pull force but also proves to be the most budget-friendly solution.

In scenarios where a one-sided magnetic field with a strong, alternating pattern is required, the Halbach Array shines. Originally designed to steer electron beams, these arrays are ideal for applications like magnetic levitation systems, brushless motors, and magnetic couplings. They are also crucial in advanced technologies like particle accelerators and free electron lasers. So, while the Halbach Array may not be your go-to for maximizing pull force on a steel surface, it certainly has its own specialized applications where it outperforms other magnetic configurations.