Introduction

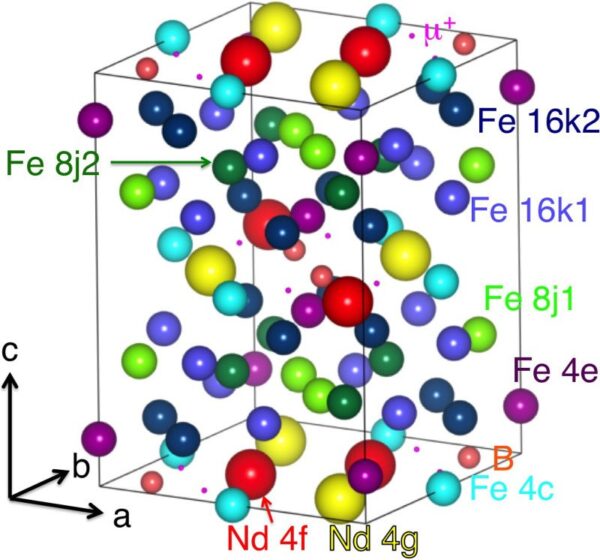

Neodymium-Iron-Boron (NdFeB) magnets are the strongest type of permanent magnets available today, made from an alloy that includes neodymium, iron, and boron. Their superior magnetic properties arise from the precise chemical composition and microstructural characteristics of the Nd2Fe14B compound. The performance of NdFeB magnets, including their magnetic strength, thermal resistance, and durability, is highly dependent on their chemical composition. Even slight variations in the elemental makeup can significantly impact their performance in various applications, ranging from consumer electronics to wind turbines. Therefore, understanding and controlling the chemical composition of NdFeB magnets is crucial for optimizing their performance and application in cutting-edge technologies. This article delves into the methodology and significance of analyzing the chemical composition of NdFeB materials, employing Inductively Coupled Plasma (ICP) Atomic Emission Spectroscopy, a state-of-the-art analytical technique.

Understanding the Chemical Composition Analysis of NdFeB Materials

The chemical composition analysis of NdFeB materials typically encompasses three key areas:

- Raw Material Analysis: This includes the chemical composition of rare earth metal raw materials and also covers industrial pure iron (Fe), boron-iron (B-Fe) alloy, and other metals such as gallium (Ga), aluminum (Al), niobium (Nb), zirconium (Zr), etc.

- Magnet Composition Analysis: The analysis of the magnet’s chemical composition is crucial when dealing with unknown magnets or when quality issues arise. If the product quality is up to standard, this analysis might not be necessary. The magnet’s composition includes rare earth metals like neodymium (Nd), praseodymium (Pr), cerium (Ce), dysprosium (Dy), holmium (Ho), gadolinium (Gd), terbium (Tb), and other metal elements such as copper (Cu), aluminum (Al), niobium (Nb), zirconium (Zr), gallium (Ga), cobalt (Co), titanium (Ti), etc.

- Analysis of Non-Metal Elements: This involves the analysis of non-metal elements’ content, such as hydrogen, oxygen, carbon, etc.

Like steel and non-ferrous metals, the analysis of NdFeB’s composition involves traditional chemical analysis methods and modern physical analysis techniques. Traditional methods, which rely on the chemical reaction of elements causing color, mass, or volume changes, have become less prevalent due to their labor-intensive nature and the significant impact of individual experience on the results. In contrast, modern physical analysis methods, which include plasma spectroscopy, atomic absorption spectroscopy, and atomic fluorescence spectroscopy, have gained popularity. Among these, plasma spectroscopy is widely used for the composition analysis of steel materials, rare earth metals and compounds, and rare earth permanent magnet materials due to its efficiency and ability to analyze multiple elements simultaneously, despite its higher cost.

ICP Atomic Emission Spectroscopy (ICP-AES)

ICP-AES combines Inductively Coupled Plasma (ICP) with Atomic Emission Spectroscopy (AES) to offer a sophisticated method for analyzing the elemental composition of materials. This technique operates on the principle that atoms or ions of the elements being tested emit characteristic radiation when excited in a light source. The process involves three main steps:

- Emission: The sample is vaporized, dissociated, or decomposed into an atomic state using an ICP light source, with atoms potentially further ionizing into ions. These atoms and ions are then excited to emit light.

- Spectroscopy: The emitted light is resolved into a spectrum arranged by wavelength using a spectrometer.

- Detection: Photodetectors measure the spectrum, allowing for qualitative analysis based on wavelength and quantitative analysis based on emission intensity.

ICP-AES can analyze 74 of the 109 elements on the periodic table, including 3d, 4d, 5d transition metals and lanthanide series rare earth metals. It is capable of performing bulk analysis (0.x% to 20%), trace analysis (0.00x% to 0.0x%), and ultra-trace analysis (0.0000x% to 0.000x%), although elements with concentrations above 30% cannot be analyzed.

ICP-AES instruments vary by excitation type and detection system, including sequential scanning, simultaneous multichannel, and full-spectrum direct-reading spectrometers, along with spark/arc direct-reading spectrometers and spectrographs.

Conclusion

The analysis of the chemical composition of NdFeB materials using ICP Atomic Emission Spectroscopy is crucial for ensuring the performance and quality of these advanced magnets. By providing detailed insights into the elemental makeup of NdFeB materials, ICP-AES plays a pivotal role in the development and quality control of high-performance magnetic materials. This sophisticated analytical technique, with its comprehensive coverage and precision, underscores the intersection of chemistry and materials science in advancing technology.