The stability of a permanent magnet’s performance is an essential indicator of its quality. This stability refers to the changes in a magnet’s magnetic properties over time due to various internal and external factors, typically represented by the rate of change in its performance indicators. Common causes of changes in magnetic performance include temperature, time, electromagnetic fields, radiation, and mechanical vibration or impact. We’ve previously discussed the temperature stability of permanent magnets in the article — Temperature Stability in Permanent Magnets: Key Coefficients Explained. In this article, we will explore the time stability of permanent magnetic materials.

Over extended periods of use or storage, environmental conditions such as temperature, humidity, and corrosive liquids can alter the physical and chemical properties of a magnet. Once magnetized, most of the magnet’s regions align in a specific direction. However, some small magnetic domains, known as demagnetization nuclei, remain disordered. Environmental factors can cause existing demagnetization nuclei to grow and new ones to form, leading to a decay in magnetic performance. This change is typically a slow and irreversible deterioration from the surface inwards, directly affecting the main performance parameters of the magnet: remanence, coercivity, or maximum energy product, potentially leading to complete failure. This loss of magnetic properties is irreversible; even re-magnetization cannot restore the magnet to its original state. In recent years, with the widespread application of neodymium-iron-boron (NdFeB) permanent magnets in sectors with long service life requirements, such as aerospace, electric vehicles, and high-power wind turbines, the time stability of NdFeB magnets has become increasingly important to designers.

Long-term Stability at Room Temperature

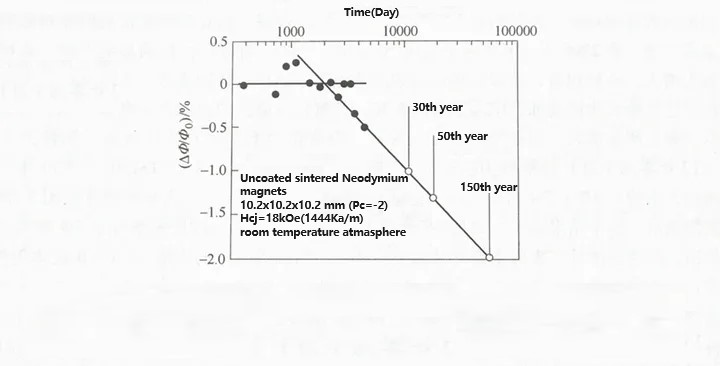

In 2013, Finnish researchers published a study showing that sintered NdFeB magnets (HcJ = 15.6kOe) placed in a room temperature environment for one year (10,000 hours) showed no detectable loss of magnetization, regardless of their Pc value. Other research teams have conducted similar long-term studies. One such team observed sintered NdFeB magnets (HcJ = 18kOe) over 12 years (4,441 days). These samples, cubic with 10.2 mm edges and no coating, with a magnetic permeability coefficient Pc = -2, were exposed to the laboratory’s atmospheric conditions, with temperatures between 22°C and 28°C, and were measured annually.

The following table shows the magnetic flux data over 12 years for eight sintered NdFeB magnet samples exposed to room temperature air.

| Test Date | Number of Days | Temp (℃) | Sample Number | Average | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Magnetic Flux Loss(%) | |||

| 2003-6-6 | 0 | N/A | 142.5 | 141.1 | 141.5 | 140.9 | 142.4 | 142.8 | 142.9 | 140.4 | 0 |

| 2004-6-18 | 377 | N/A | 142.6 | 141.3 | 141.6 | 140.9 | 142.8 | 142.6 | 142 | 140.5 | 0.084 |

| 2005-6-10 | 734 | 28 | 142.2 | 140.8 | 141.3 | 140.7 | 142.4 | 142.5 | 142.9 | 140.4 | -0.0112 |

| 2005-11-25 | 901 | 22 | 142.7 | 141.4 | 141.9 | 141.3 | 143 | 143 | 143.3 | 140.4 | -0.217 |

| 2006-6-20 | 1109 | 24 | 142.8 | 141.5 | 141.9 | 141.2 | 142.8 | 143 | 143.5 | 140.7 | -0.002 |

| 2007-6-21 | 1475 | 23 | 142.6 | 141.2 | 141.7 | 141 | 142.8 | 142.8 | 142 | 140.5 | -0.25 |

| 2008-6-17 | 1836 | 24 | 142.6 | 141.2 | 141.8 | 141 | 142.6 | 142.9 | 142 | 140.3 | -0.195 |

| 2009-6-24 | 2208 | 23.5 | 142.7 | 141.3 | 141.4 | 141.7 | 142.8 | 142.9 | 142 | 140.3 | -0.187 |

| 2010-6-28 | 2577 | 23.5 | 142 | 141 | 141.6 | 141.9 | 142.4 | 142.5 | 142.7 | 140.1 | -0.452 |

| 2011-6-17 | 2931 | 22.8 | 142.6 | 141 | 141.6 | 141.9 | 142.6 | 142.7 | 142.9 | 140.2 | -0.365 |

| 2012-6-29 | 3308 | 22.7 | 142.5 | 141.1 | 141.6 | 141 | 142.6 | 142.8 | 142.9 | 140.2 | -0.365 |

| 2013-7-16 | 3690 | 24.5 | 142.2 | 140.6 | 141.6 | 141 | 142 | 142.2 | 142.4 | 139.7 | -0.526 |

| 2015-8-7 | 4441 | 24.5 | 141.8 | 140.5 | 141 | 141 | 141.8 | 142 | 142.2 | 139.6 | -0.448 |

- Note:

- Visible rust was observed on the magnet surfaces after 6 years (approximately 2,208 days).

- The average magnetic flux loss was calculated by adjusting the data to a standard temperature of 23°C using a temperature coefficient of -0.09%/°C.

The logarithmic graph below depicts the rate of magnetic flux loss over time for NdFeB magnets at a room temperature atmospheric environment with HcJ = 18kOe (Pc = -2).

The data indicate that the relative magnetic flux loss was negligible for the first six years, with a turning point around 2,208 days. After six years, oxidation and corrosion began on the magnet surfaces, which would likely worsen over time, accelerating the rate of performance degradation. Extrapolating the magnetic flux loss from the 12-year measurement to 30-50 years, the projected loss is less than 1% for 30 years and approximately 1.3% for 50 years, with a 2% loss expected around 150 years (indicated by the hollow circles in the graph above).

This suggests that the lifespan of the tested sintered NdFeB magnets, even without corrosion-resistant coating, is quite long, conservatively estimated at 30-50 years, assuming they are not subjected to temperatures exceeding their rated maximum.

Usually, significant magnetic flux loss stems from surface oxidation or corrosion, which is irreversible. Among various rare-earth permanent magnets, this loss is most severe for sintered NdFeB. However, with composition optimization and surface protection treatments, the oxidation resistance and corrosion resistance of sintered NdFeB magnets have significantly improved. Therefore, with proper surface protection, the lifespan of sintered NdFeB magnets with sufficiently high HcJ can easily exceed 30-50 years under appropriate temperature conditions.

Long-term Stability at High Temperatures

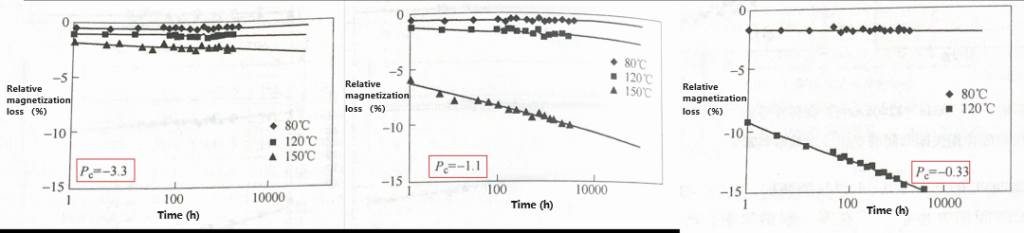

The following graph shows the relative magnetic flux loss over time for magnets with different Pc values and HcJ = 20.1 kOe at temperatures of 80°C, 120°C, and 150°C.

It is evident that the higher the storage temperature, the faster the relative magnetic flux loss occurs. Magnets with lower absolute Pc values exhibit significantly greater initial and long-term magnetization losses compared to those with higher Pc values, with both types of losses increasing substantially as the temperature rises. If it is not feasible to further increase the intrinsic coercivity (HcJ) due to technical or cost considerations, raising the absolute value of Pc can effectively suppress magnetization losses.

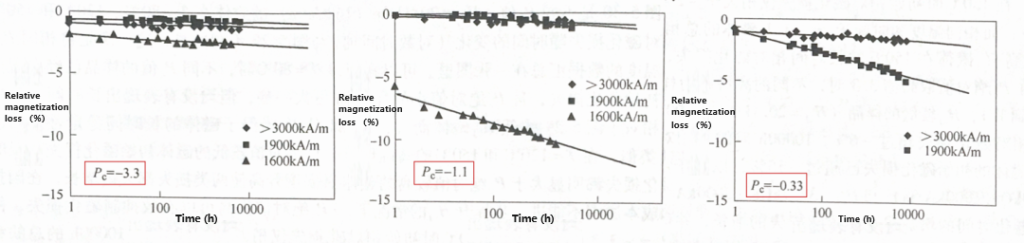

The relationship between relative magnetization loss over time at various temperatures for magnets with different HcJ and Pc values demonstrates that HcJ has a significant impact on high-temperature magnetization loss. The higher the HcJ, the lower the magnetization loss, indicating that magnets intended for high-temperature stability must possess a high HcJ. Concurrently, the magnetic permeability coefficient Pc also determines the long-term high-temperature magnetization loss of the magnet.

By considering these factors, engineers and designers can make informed decisions when selecting and using NdFeB magnets, ensuring their long-term stability and effectiveness in various applications. Through careful material selection and protective measures, NdFeB magnets can maintain their performance over extensive periods, even in challenging environmental conditions.

Conclusions

The analysis of the relationship between relative magnetization loss over time at various temperatures for magnets with different HcJ and Pc values shows that HcJ has a crucial impact on magnetization loss at high temperatures. A higher HcJ results in lower magnetization loss, indicating that for high-temperature stability, magnets must have a high HcJ value. At the same time, the magnetic permeability coefficient Pc also determines the magnet’s long-term high-temperature magnetization loss.

In conclusion, if we define the service life of a magnet as the time corresponding to a magnetic flux loss rate of 5%, even without a corrosion-resistant coating, the tested sintered NdFeB magnets still have a considerably long life expectancy. Conservatively estimated, their lifespan could range between 30 to 50 years. This is based on the assumption that the magnets operate within their temperature specifications.

It’s important to note that substantial magnetic flux loss usually originates from irreversible losses due to surface oxidation or corrosion. In the realm of rare earth permanent magnets, sintered NdFeB magnets are most susceptible to such losses. However, thanks to advancements in composition optimization and surface protection treatments, the resistance of sintered NdFeB magnets to oxidation and corrosion has greatly improved. Therefore, when the magnet surface is well-protected, and the magnet has a sufficiently high HcJ, its service life can exceed 30 to 50 years, even under higher temperature conditions.

This understanding of the temperature and time stability of NdFeB magnets allows for their reliable application in fields that demand longevity, such as in renewable energy and transportation. The ongoing research and development in material science promise even greater improvements in the performance and durability of these critical components in the future.