In the realm of magnetism, where functionality intertwines with innovation, the crafting of Halbach Arrays stands as a testament to scientific artistry. Striking the perfect harmony between potency and economic viability often emerges as a challenging feat. This narrative unfolds the intricate considerations pivotal to the foundational design elements of Halbach Arrays, a topic of paramount importance for aficionados and professionals alike.

Diverse Interpretations in Array Configurations

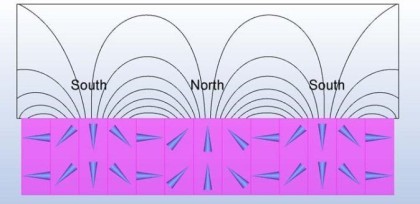

The nomenclature “Halbach Array” has permeated the technical jargon, often employed broadly to describe a magnetic system where a rotational pattern dictates the magnet’s orientation. Predominantly, Planar Magnet Arrays adopt this methodology, showcasing a 90° directional shift from one magnetic component to the next. Introducing magnets with horizontal orientations, or the so-called “Bucking Magnets,” diversifies the design possibilities.

When “Bucking Magnets” come into play, the resulting structure might deviate from the traditional Halbach Array. Nonetheless, the term “Halbach Array” is commonly retained in technical discourse.

The Art of Bucking Magnet Arrays

Visual representations readily found online predominantly illustrate Halbach Arrays with a 90° orientation shift. However, the spectrum of designs is vast and varied. While a 90° variation is somewhat rudimentary, integrating additional elements with minimized angles can emulate a more genuine circumferential orientation, enhancing the system’s efficacy.

For instance, as illustrated in the diagram below, employing 45° angles between magnets enhances the alignment, closely mirroring a true circumferential arrangement and thereby bolstering the system’s overall efficiency.

Delving into the Utility of Bucking Magnets

The debate remains open on the merits of intricate designs demanding higher precision. Generally, an increase in the number of elements correlates with enhanced angular resolution, leading to a more uniform and potent magnetic field. Yet, the law of diminishing returns prevails, highlighting the point where the complexities of fabrication overshadow the advantages in magnetic field intensity.

In the grand scheme of magnetic circuitry, designers juggle between application necessities and financial constraints. While a Halbach Array necessitates additional expenditure, it compensates by potentially diminishing the magnet mass and amplifying operational performance.

Critical Design Variables

Several factors come under scrutiny during the design phase, including:

- Operational gap: The distance between the work-piece and the magnet array in various configurations.

- Operational conditions: Encompassing temperature, rotational dynamics, and environmental constituents.

- External demagnetizing influences: Particularly pertinent for rotors.

- Service longevity requirements.

- Financial implications.

- Spatial constraints allocated for the array.

Recognizing the intertwined nature of design, utility, and external factors is crucial across various applications, and Halbach Arrays are no exception.

In the innovative landscape of magnetic solutions, EPI Magnets emerges as a beacon of excellence, offering unparalleled expertise in the realm of Halbach Arrays. With a legacy spanning over two decades, EPI Magnets prides itself on spearheading custom Halbach Array assemblies, catering to a diverse spectrum of industrial and scientific fields. Our proficiency is not just confined to the development and production but extends to the meticulous installation of multi-segmented Planar and Circular Halbach Array assemblies.

Our offerings are distinguished by their robust magnetic fields and exceptional uniformity, a testament to our commitment to quality and precision. Whether you seek simple configurations or complex assemblies for high-stakes applications, EPI Magnets stands equipped to meet the most demanding of magnetic challenges. Our comprehensive services encompass the entire spectrum from design & proof-of-concept to cost-effective mass production, ensuring our clients’ visions transform into tangible solutions.

At EPI Magnets, we understand that our clients’ needs are as diverse as the industries we serve. That’s why we offer an extensive range of products, including but not limited to, Linear Motor Magnet Tracks, Magnetic Couplings, and Magnetic Rotor Assemblies. Our Halbach Arrays, renowned for concentrating magnetic fields on one side while reducing the field to nearly zero on the opposite, find their utility in various applications, from motors and generators to high-precision scientific equipment.