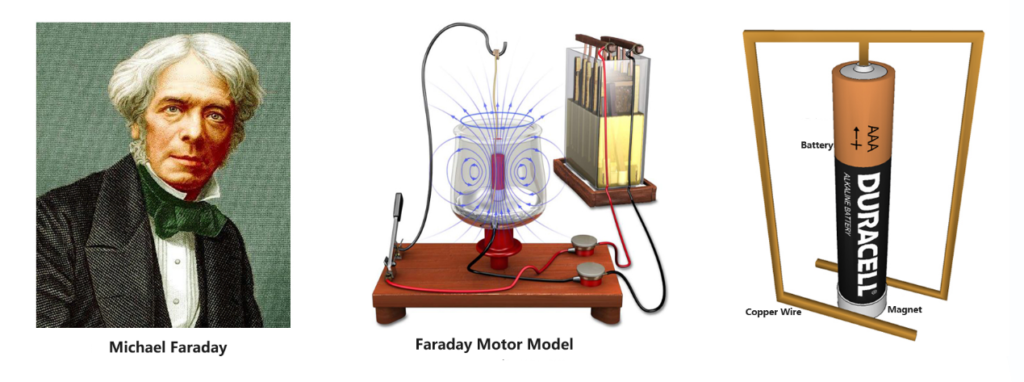

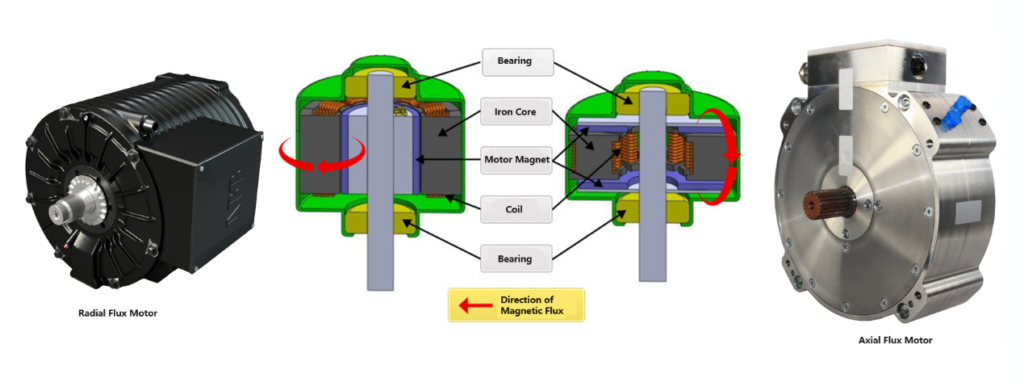

Motors are typically classified based on the orientation of their magnetic flux, with radial and axial flux motors being the predominant types. The axial flux motor, first conceptualized by Michael Faraday in 1821, represents a significant milestone in the evolution of motor technology. Despite its early inception, the axial flux motor’s development was initially overshadowed by the radial flux motor, invented by Tomas Davenport in 1834. This was largely due to the material and technological constraints of the era.

Resurgence of Axial Flux Motors in Modern Engineering

In contemporary motor design, axial flux motors have experienced a resurgence, driven by advancements in materials science and a greater emphasis on efficiency and compactness. These motors, characterized by their planar air gap and a magnetic field that runs parallel to the axis of rotation, align well with the current trends in the motor industry that prioritize high speed, reduced weight, and enhanced efficiency.

Key Advantages of Axial Flux Motors

- Compact and Lightweight Design: Axial flux motors are known for their slim profile, offering significant space and weight advantages over traditional designs, making them ideal for applications where space is at a premium.

- High Torque and Power Density: They excel in delivering high torque relative to their size, a critical factor in many high-performance and electric vehicle applications.

- Minimal End-Winding: The reduced end-turn winding contributes to the overall compactness and efficiency of these motors.

- Superior Cooling: Their design facilitates effective heat dissipation, a key factor in enhancing performance and extending the motor’s lifespan.

Given these advantages, axial flux motors are increasingly favored in scenarios demanding high torque density and efficient space utilization. The common association of high power density with high rotational speeds overlooks the importance of torque density. Prioritizing torque density is essential for optimizing performance and longevity, especially in high-speed applications.

Innovative Magnet Design in Axial Flux Motors

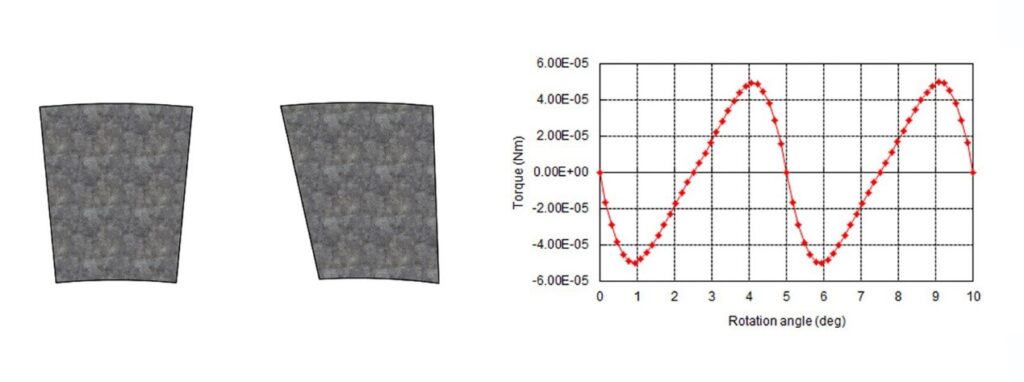

The magnet design in axial flux motors is a critical aspect that directly influences their performance. Traditional motor designs often suffer from cogging torque due to the interaction between the permanent magnets and the stator teeth. This interaction can cause undesirable torque ripple, vibration, and noise. By adopting a skewed fan shape for the magnets, axial flux motors can significantly reduce these effects, leading to smoother operation.

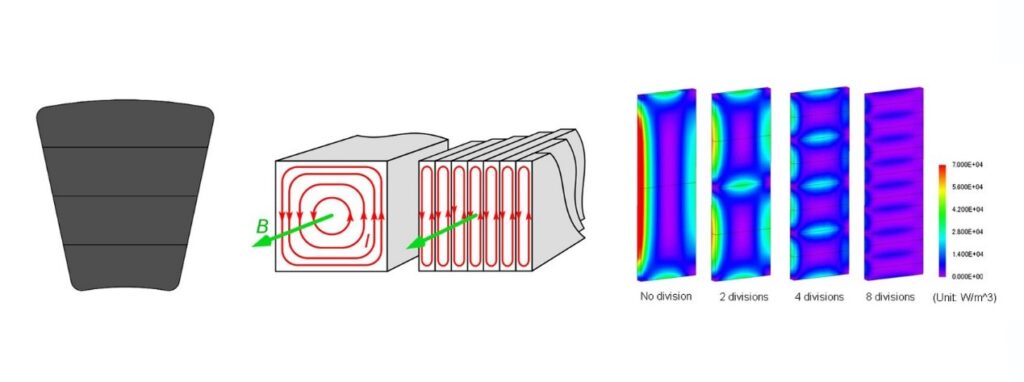

Addressing eddy current losses is another crucial factor in the design of axial flux motors. Eddy currents generated within the motor can lead to heat-induced demagnetization, adversely affecting efficiency. To combat this, the use of segmented magnet technology to produce laminated magnets is an ideal choice. These approaches not only reduce eddy current losses but also contribute to the motor’s overall thermal management, ensuring consistent performance under various operating conditions.

Conclusion

The axial flux motor, with its innovative design and efficient use of materials, marks a significant step forward in motor technology. Its resurgence in recent years is a testament to the ongoing advancements in electromechanical design and materials science. As the demand for more efficient, compact, and high-performance motors continues to grow, axial flux motors are poised to play a pivotal role in shaping the future of motor technology.