Introduction

Building on our previous overview of the Production process of sintered Neodymium magnets, this series of articles delves deeper into the key technologies involved in the production of these magnets. In this first installment, we focus on the initial phase: raw material preparation and alloy melting and casting.

Raw Material Preparation and Alloy Fabrication

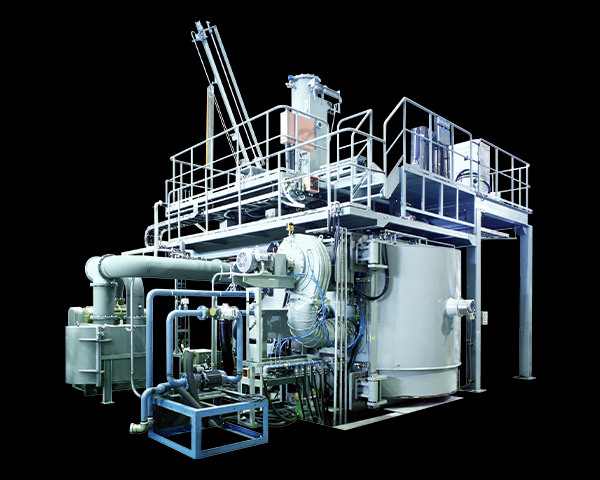

The fabrication of sintered Neodymium magnets starts with careful preparation of raw materials, typically involving pure metals or intermediate alloys. These materials are subjected to medium-low frequency induction melting under vacuum or inert gas conditions, utilizing electromagnetic induction heating to generate eddy currents within the materials for efficient melting. This process ensures a uniform melt and mitigates the loss of rare earth elements due to evaporation.

Melting Process

The melting process in the production of Neodymium magnets is a critical step where the raw materials are transformed into a usable alloy. Rare earth raw materials are typically used in pure metal form, although cost considerations sometimes lead to the use of rare earth alloys such as praseodymium-neodymium metal, lanthanum-cerium metal, mixed rare earths, and dysprosium-iron alloy. Components with high melting points, such as boron, molybdenum, and niobium, are often added in the form of iron alloys.

NdFeB magnets are characterized by their multiphase metallic nature. A rich neodymium phase is essential for high coercivity, while a boron-rich phase is also vital. The initial formula generally contains more rare earth and boron than the stoichiometric R2Fe14B composition to compensate for losses during melting and sintering due to reactions with crucible materials and evaporation. In cases where the grain boundary phase composition is adjusted (especially with the addition of copper, aluminum, or gallium), the boron content might be slightly lower than the stoichiometric composition.

To reduce impurities in the alloy, strict control over the purity of raw materials is essential. Surface oxidations and attachments must be thoroughly removed to ensure high-quality alloy production. The melting process involves eddy currents generated by an alternating magnetic field within the materials. These eddy currents, affected by the skin effect, concentrate on the surface of the materials. If the raw material chunks are too large, the eddy currents can’t penetrate to the center, making internal melting impractical. Therefore, the size of the raw material pieces is adjusted according to the frequency of induction melting, typically controlled to be 3-6 times the depth of the skin effect. The table below shows the relationship between power frequency, skin depth, and optimal raw material size, indicating that higher frequencies require smaller raw material sizes due to the more pronounced skin effect:

Power Frequency (Hz) | Skin Depth (mm) | Optimal Raw Material Size (mm) |

50 | 73 | 220-440 |

150 | 42 | 125-250 |

1000 | 16 | 50-100 |

2500 | 10 | 30-60 |

4000 | 8 | 25-50 |

8000 | 6 | 15-35 |

This precise control over the melting process is crucial in ensuring the uniformity and quality of the resulting alloy, setting the foundation for the production of high-quality Neodymium magnets.

The selection of the melting frequency is a crucial factor, influenced significantly by another key function of induction melting – electromagnetic stirring. This process involves the interaction between the molten metal and the alternating magnetic field, promoting the melting of un-melted solids and homogenization of the molten metal. The magnitude of electromagnetic force is inversely proportional to the square root of the current frequency, meaning too high a frequency can weaken the electromagnetic stirring effect of the alternating power source. In practical production, the frequency range used is typically around 1000 to 2500 Hz, and the size of the raw materials is kept under 100mm to ensure effective melting and stirring.

The placement of raw materials inside the crucible is a meticulous process that takes into account the induced magnetic field and the spatial distribution of temperature during melting. Induction coils, usually wrapped around the outer side of the crucible, create the strongest magnetic field on the inner side of the crucible, gradually weakening towards the center. However, the sides, bottom, and top opening of the crucible are the primary channels for heat loss. As a result, the temperature is moderate on the lower side of the crucible, with lower temperatures at the top layer and the middle of the bottom, and the highest temperature in the middle section. Therefore, it’s advisable to place smaller chunks of low-melting-point materials densely at the bottom of the crucible; high-melting-point and larger materials in the middle to lower sections; and large chunks of low-melting-point materials loosely on top to prevent bridging.

Modern techniques commonly utilize continuous melting-casting processes, where raw materials are sequentially added to the high-temperature crucible through a feeding chamber. To control the evaporation of rare earth materials, pure iron is usually added first to initiate melting, followed by the sequential addition of high-melting-point metals or alloys, and finally the rare earth elements. This method ensures an efficient and controlled melting process, crucial for the quality of the final NdFeB magnets.

Casting

In the process of creating Neodymium magnets, the casting stage is crucial, especially for binary or ternary rare earth alloys. When cooled slowly (approaching equilibrium state), these alloys inevitably form α-Co or α-Fe phases. These soft magnetic phases at room temperature can significantly damage the permanent magnetic properties of the magnet, necessitating rapid cooling to suppress their formation.

Traditional ingot mold casting techniques have continuously evolved to reduce the thickness of alloy ingots for achieving the necessary rapid cooling effect. The advantages of ingot mold casting include low equipment cost and simplicity in operation, meeting general production requirements for magnets. However, this method has its drawbacks, such as the uneven size of grains and the frequent emergence of α-Co or α-Fe phases. Long-term heat treatment of the alloy ingots at temperatures below their melting points can help eliminate these phases, but it leads to an accumulation of the rich Nd phase, which is not conducive to the optimal distribution of the grain boundary phase in sintered magnets.

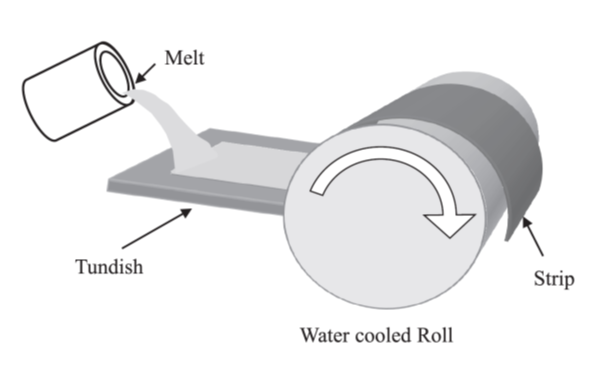

To further reduce the thickness of alloy ingots, a “disc-scraper” structure, similar to spreading pancake batter, has been developed, achieving an alloy thickness of about 1cm. However, the increase in alloy area poses significant challenges to the collection process in large-capacity melting furnaces. An alternative and effective technological development took a different approach, starting from the extremely high cooling rates required for the preparation of rapidly quenched Nd-Fe-B alloys. This led to the creation of strip casting or SC (speed quenching thin sheets) technology. In this process, molten alloy is poured through a channel onto a rapidly rotating water-cooled metal wheel, producing thin alloy strips with a thickness of 0.2 to 0.6mm and an ideal phase composition and texture. Strip casting results in a more uniform distribution of the rich Nd phase and reduces the total rare earth content, beneficial for achieving high-performance magnets at a lower cost. However, the decrease in the volume fraction of the rich Nd phase compared to magnets produced using ingot mold casting increases the brittleness of the magnets, making subsequent processing more challenging.

Conclusion

The intricate process of casting in the production of NdFeB magnets, highlighted by rapid cooling techniques and advanced technologies like strip casting, underscores the precision and innovation inherent in this field. As we have seen, each step in the production process, from the careful selection of raw materials to the sophisticated methods of casting, plays a vital role in determining the quality and performance of the final magnets. This meticulous approach not only ensures the production of high-quality magnets but also reflects the ongoing commitment to technological advancement in the realm of magnetic materials. Stay tuned for our next installment in this series, where we will delve into the subsequent stages of NdFeB magnet production, further unraveling the complexities of this fascinating process.