Introduction

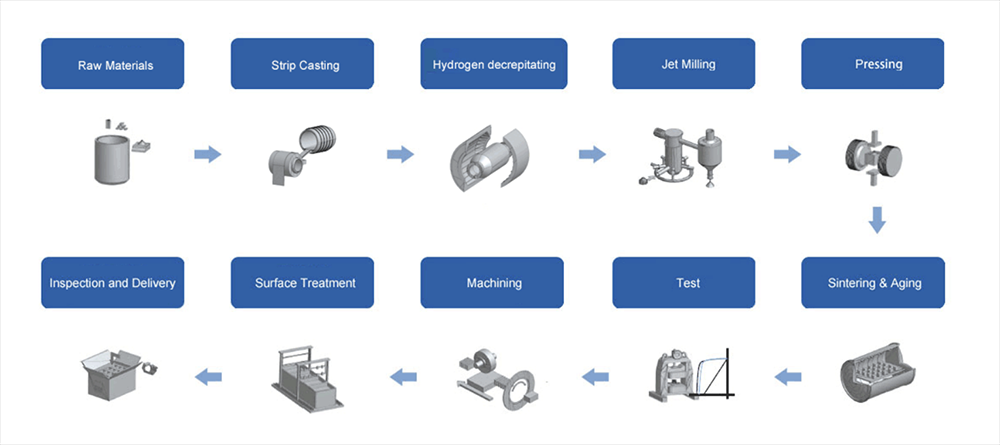

Following our exploration of raw material preparation and alloy melting in the first part Neodymium Magnet Production Series Part 1 – Raw Material Preparation and Alloy Melting of our NdFeB magnet production series, we now turn our attention to a crucial subsequent phase: the milling process. Integral to the manufacturing of NdFeB (Neodymium-Iron-Boron) magnets, milling transforms the carefully prepared alloys into the fine powder necessary for crafting high-performance magnets.

Milling, a process that determines the shape, average size, and distribution of the powder particles, directly influences the magnet’s inherent properties. The characteristics of the powder, including its loose packing density, tap density, angle of repose, flowability, compressibility, and internal and external friction coefficients, play a vital role in subsequent stages of magnet production. These stages include powder filling, magnetic field orientation, billet pressing, and demolding, as well as the formation of the magnet’s microstructure during sintering and heat treatment processes.

The ideal microstructure of a sintered magnet consists of fine and uniform main-phase grains surrounded by smooth, thin boundary phases, with the easy magnetization direction of the grains aligned as uniformly as possible. Imperfections such as voids, large grains, or significant amounts of soft magnetic phases can severely reduce the intrinsic coercivity of the magnet. Similarly, grains whose easy magnetization directions deviate from the orientation direction can lower both the magnet’s remanence and the squareness of its demagnetization curve.

Our journey through the milling process will reveal how the alloy ingots or rapidly quenched flakes are converted into single-crystal particles with an average size of 3-5μm and a maximum particle size of less than 20μm, closely resembling a spherical shape. We will also discuss the importance of controlling the proportion of overly fine grains to prevent severe oxidation of the powder and, when necessary, how surface treatments of the powder can enhance its antioxidation capabilities, thereby improving filling and pressability.

Join us as we delve into the complexities of the milling process in NdFeB magnet manufacturing and uncover how this critical stage shapes the quality and capabilities of one of the most powerful types of magnets used in modern technology.

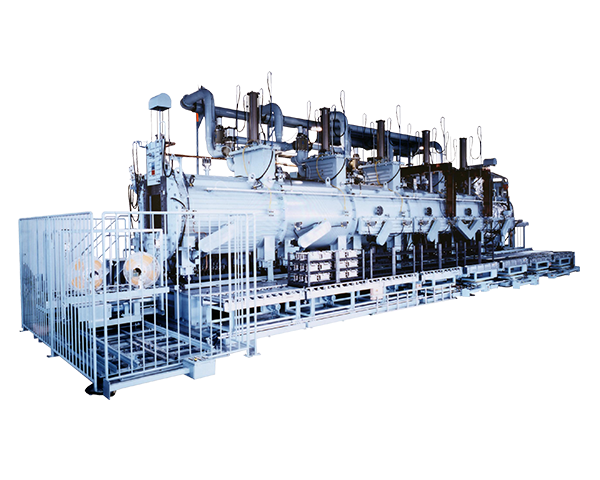

Hydrogen Decrepitation (HD) Process

The Hydrogen Decrepitation (HD) process plays a fundamental role in the milling phase of NdFeB magnet production. This unique method leverages the reactive nature of hydrogen with the alloy to facilitate the breakdown of the material into a fine powder, which is essential for the high-quality magnet production.

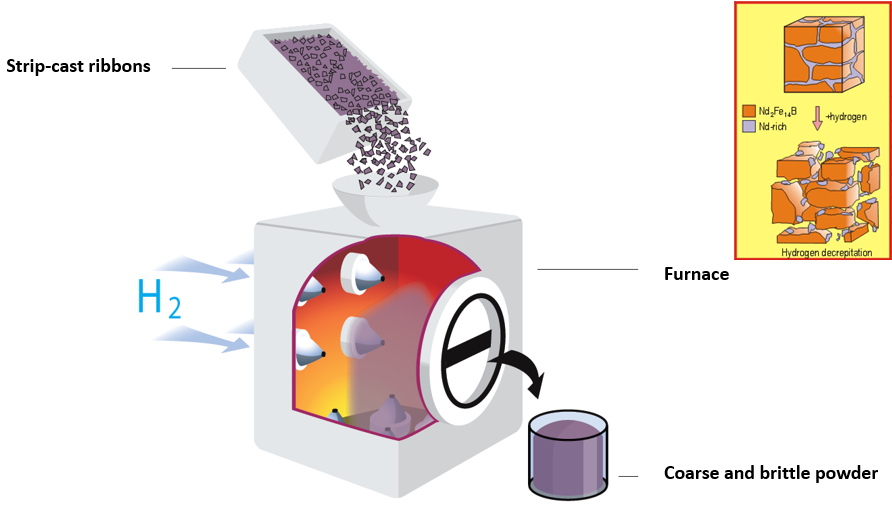

Principle and Mechanism:

The HD process begins by exposing the NdFeB alloy to hydrogen gas. Hydrogen molecules penetrate the alloy and react with the rare earth elements, particularly neodymium. This reaction causes the alloy to expand and creates internal stresses, leading to what is known as “hydrogen decrepitation.” The result is the fragmentation of the alloy into smaller particles, effectively ‘crumbling’ the solid mass into a powder form.

Advantages of HD Process:

One of the primary advantages of the HD process is the ability to produce powders with an ideal particle size for magnet production. The process creates particles that are uniform and fine, typically within the range of 3-5μm. This uniformity is crucial for achieving consistent magnetic properties in the final product. Additionally, the HD process is relatively low-energy compared to mechanical milling methods, making it more efficient and environmentally friendly.

Impact on Magnet Quality:

The quality of the powder produced through the HD process directly impacts the performance of the final magnet. A fine and uniform powder ensures a homogenous microstructure in the sintered magnet, which is critical for achieving high coercivity and magnetic strength. Moreover, the HD process allows for better control over the oxidation of the particles, which can be detrimental to the magnet’s performance if not properly managed.

Challenges:

Despite its advantages, the HD process does present challenges. The most significant is controlling the reaction between hydrogen and the alloy to ensure uniform decrepitation without overexposure, which can lead to excessive oxidation. Additionally, the handling of hydrogen gas requires careful safety measures due to its flammability and explosiveness.

In conclusion, the Hydrogen Decrepitation process is a vital step in the NdFeB magnet production, offering a balance of efficiency and quality. Its ability to produce fine, uniform powder paves the way for the manufacturing of high-performance magnets, making it a preferred choice in the industry.

Mechanical Milling Techniques

In the NdFeB magnet manufacturing process, mechanical milling plays a crucial role in transforming alloy castings into fine powder. This section of the production involves a combination of techniques and equipment, starting with the initial breakdown of the alloy.

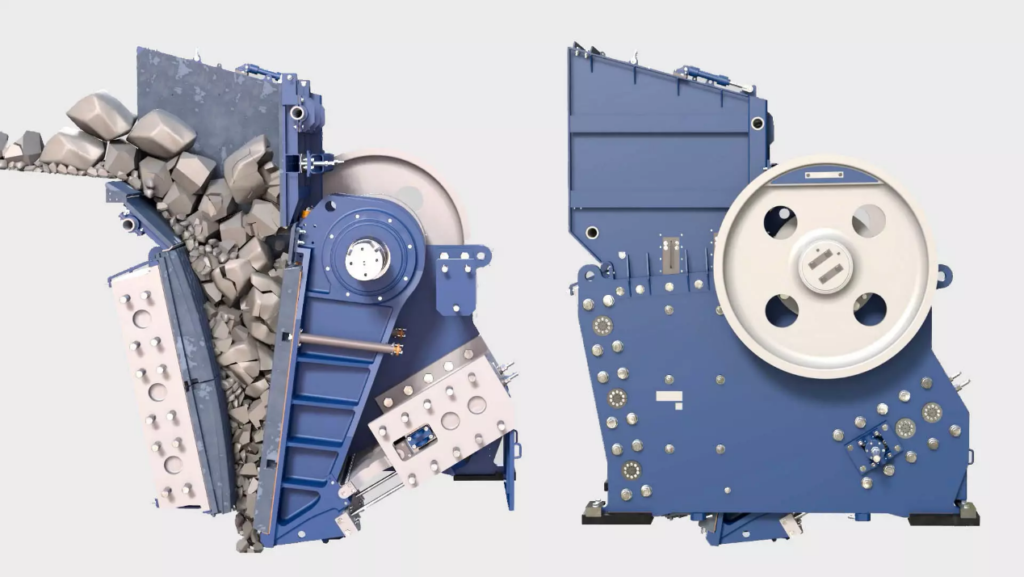

Initial Breakdown with Jaw Crusher:

The process begins with the use of a Jaw Crusher or similar mechanical crushing equipment. Given the hardness and brittleness of rare earth-transition metal intermetallic compounds, the alloy ingots are easily broken down into smaller chunks. This initial step is vital as it prepares the alloy for further reduction into fine particles.

Subsequent Mechanical Milling:

After the initial breakdown, the smaller pieces of the alloy are subjected to further mechanical milling. This stage aims to achieve an average particle size of 3-5μm. However, it is essential to be mindful of the contamination from equipment wear, which can inevitably affect the quality of the powder. The milling process must be carefully controlled to minimize such impurities.

Challenges and Considerations:

One of the challenges in mechanical milling is managing the oxidation tendency of rare earth metals and their compounds. The process must be optimized to ensure that the particle size reduction does not lead to significant oxidation, which can detrimentally affect the magnet’s properties. Additionally, maintaining equipment to reduce contamination and managing the heat generated during milling are critical for preserving the quality of the powder.

Innovation in Milling Techniques:

To address these challenges, ongoing innovations and improvements in milling techniques are being implemented. This includes the development of more efficient milling equipment and processes that minimize contamination and oxidation, ensuring the production of high-quality magnet powders.

In summary, the mechanical milling techniques in NdFeB magnet production involve a careful balance between size reduction, contamination control, and oxidation management. The process, starting from the Jaw Crusher to advanced milling equipment, highlights the intricate relationship between physical processing and material properties in producing high-performance magnets.

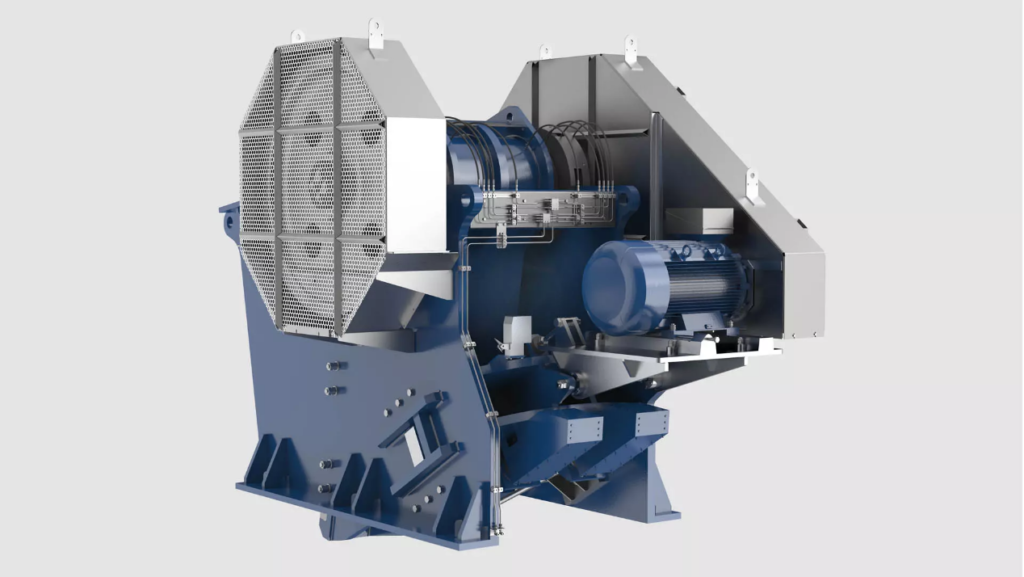

Jet Milling Method

The Jet Milling method is a sophisticated technique employed in the milling process of NdFeB magnet production. This mechanical process plays a crucial role in achieving the desired particle size and distribution for high-performance magnets.

Working Principle of Jet Milling:

Jet Milling utilizes high-velocity air or other gases to grind the alloy into fine particles. In this process, the pre-crushed alloy from the initial mechanical milling stage is fed into a jet mill, where it is subjected to a high-speed airstream. The collision and shear forces generated by the air jets reduce the particles to a fine powder. The particle size can be precisely controlled by adjusting the air pressure, the feed rate, and the configuration of the mill.

Advantages and Applications:

One of the key advantages of the Jet Milling method is its ability to produce extremely fine and uniform particles, typically in the range of 3-5μm, which is ideal for NdFeB magnets. This method is particularly effective for materials that are hard and brittle, as it avoids the heat generation associated with traditional mechanical milling, thus reducing the risk of oxidation. Moreover, Jet Milling allows for a relatively contamination-free process, as the milling takes place without any contact with metal surfaces.

Challenges in Jet Milling:

Despite its advantages, Jet Milling poses certain challenges. The process can be energy-intensive and may require specific adjustments to optimize for different alloy compositions. Controlling the particle size distribution and minimizing the production of ultra-fine particles, which can lead to increased oxidation, are critical aspects of the process.

Optimization and Technological Advances:

To overcome these challenges, ongoing technological advancements focus on optimizing the jet milling process. Innovations include the development of specialized jet mills that can handle different materials more efficiently and the use of inert gases like nitrogen or helium to reduce the risk of oxidation. These advancements contribute to the production of high-quality magnet powders, essential for the manufacturing of NdFeB magnets.

In conclusion, the Jet Milling method is an integral part of the NdFeB magnet manufacturing process, offering precision and efficiency in powder production. Its ability to produce fine, uniform particles while minimizing contamination and oxidation is vital for the production of high-performance magnets.

Ammonia Gas Stream Milling

In the advanced landscape of NdFeB magnet production, ammonia gas stream milling emerges as a notable technique, complementing the traditional jet milling process. This method is particularly tailored for producing fine magnetic powders with enhanced characteristics.

The Ammonia Gas Stream Milling Process:

Ammonia gas stream milling is a unique variant of the jet milling method, where ammonia gas, instead of air or inert gases, is used as the milling medium. The process involves feeding the pre-crushed NdFeB alloy into a milling chamber where high-pressure ammonia gas is injected. The gas stream’s velocity and pressure cause the particles to collide and fracture, reducing them to a fine powder. The use of ammonia gas not only aids in achieving the desired particle size but also plays a role in preventing oxidation during the milling process.

Benefits and Specific Applications:

The incorporation of ammonia gas in the milling process offers several advantages. One significant benefit is the reduction in the risk of oxidation, a common challenge in the milling of rare earth magnets. The presence of ammonia gas creates an environment less conducive to oxidation, thus preserving the quality of the powder. Additionally, ammonia gas stream milling can result in finer particle sizes and a more uniform particle distribution compared to traditional air-based jet milling.

Challenges and Technological Considerations:

Despite its advantages, ammonia gas stream milling presents its own set of challenges. The handling and use of ammonia gas require stringent safety measures due to its toxic and corrosive nature. Moreover, precise control over the milling parameters is crucial to ensure the consistency and quality of the powder.

Optimizing the Process:

To optimize the ammonia gas stream milling process, ongoing research and development focus on enhancing the efficiency and safety of the technique. Innovations include the development of advanced milling chambers designed to handle ammonia gas safely and the implementation of controlled environments to minimize the risk of gas leakage.

In summary, ammonia gas stream milling represents a significant advancement in the field of NdFeB magnet production. By utilizing ammonia gas, this method not only achieves finer and more uniform particles but also addresses the critical issue of oxidation, thereby contributing to the production of high-quality magnets. This technique showcases the continuous evolution and innovation in the realm of magnetic materials processing.

Challenges and Advances in Milling Process

The milling process in NdFeB magnet production, while essential, presents several challenges that require constant innovation and technological advancement to ensure the production of high-quality magnets.

Addressing Particle Size and Distribution:

One of the primary challenges in the milling process is achieving and maintaining the desired particle size and distribution. The magnetic properties of NdFeB magnets are highly sensitive to these factors. Any inconsistency can lead to variations in the magnets’ performance. Ensuring a uniform particle size, typically in the range of 3-5μm, is crucial for achieving the optimal density and magnetic properties in the final product.

Controlling Oxidation:

Another significant challenge is controlling the oxidation of the powder during the milling process. Rare earth elements, particularly neodymium, are prone to oxidation, which can degrade the magnetic properties of the final product. Advanced milling processes, including the use of inert gases or ammonia gas, are employed to create an environment that minimizes oxidation.

Equipment Wear and Contamination:

The wear of milling equipment, such as in mechanical and jet milling, can introduce contaminants into the powder, affecting the purity and quality of the final magnet. Developing wear-resistant materials for milling equipment and optimizing the milling conditions are ongoing areas of research.

Advances in Milling Technology:

To overcome these challenges, the field of NdFeB magnet production has seen significant technological advancements. These include the development of more efficient milling systems that can produce finer and more uniform powders with reduced contamination. Innovations in cryogenic milling, where milling is performed at very low temperatures, have also been explored to prevent heat buildup and reduce oxidation risks.

Focus on Sustainability:

With growing environmental concerns, there is also a focus on making the milling process more sustainable. Efforts are being made to reduce energy consumption and minimize waste during milling, contributing to the overall sustainability of NdFeB magnet production.

In conclusion, while the milling process in NdFeB magnet production faces several challenges, ongoing technological advancements and innovations continue to enhance its efficiency and effectiveness. These improvements are crucial in maintaining the high quality and performance of NdFeB magnets, which are integral in various modern technologies.

Conclusion

As we conclude our exploration of the milling process in NdFeB magnet production, it’s clear that this phase is more than just a step in manufacturing; it’s a crucial juncture where science and precision engineering intersect to define the quality and performance of the final magnets.

Synthesis of Milling Techniques:

The journey from raw alloy to fine magnetic powder through various milling techniques, including Hydrogen Decrepitation, Mechanical Milling, Jet Milling, and Ammonia Gas Stream Milling, showcases the intricate balance of physical forces, chemical reactions, and technical expertise. Each method, with its unique advantages and challenges, contributes significantly to achieving the desired physical and magnetic properties in the NdFeB magnets.

Impact on Magnet Performance:

The particle size, shape, and distribution achieved through these milling processes directly influence the magnetic strength, durability, and consistency of the magnets. The precision in milling not only determines the efficiency of subsequent manufacturing stages like pressing and sintering but also the application potential of the magnets in various high-tech industries.

Looking Forward:

As the demand for stronger, more efficient magnets continues to grow, the importance of refining and improving the milling process cannot be overstated. Future advancements in milling technology, aimed at achieving finer control over particle characteristics while minimizing environmental impact, will be pivotal in driving the evolution of NdFeB magnet production.

In our next installment of this series, we will delve into the Orientation and Forming Neodymium Magnet Production Series: Part 3 – Orientation and Forming of the magnetic powder, another critical phase in the journey of creating NdFeB magnets. Stay tuned as we continue to uncover the fascinating process behind these powerful magnets that are integral to modern technology.

In conclusion, the milling process in NdFeB magnet production is a testament to the synergy of material science and engineering. It’s a process that not only shapes the powder but also the future of magnet technology.