Introduction

Welcome back to our Neodymium Magnet Production Series. In our previous articles, we briefly introduced the production and preparation process of sintered Neodymium permanent magnets, giving a general overview of their production stages and key equipment (The Process of Making Neodymium Magnets). Building on this foundation, Part 3 delves into the critical stages of orientation and shaping. These processes are essential for determining the final performance of the magnets. After the intricate milling and alloy preparation, orientation and shaping stand as a testament to the precision engineering in Neodymium magnet production. This phase ensures the finely milled particles are correctly aligned and shaped, setting the stage for the magnet’s superior magnetic properties. Join us as we explore how meticulous orientation and advanced pressing techniques play a pivotal role in creating some of the most powerful magnets for modern technologies.

Orientation Forming Techniques

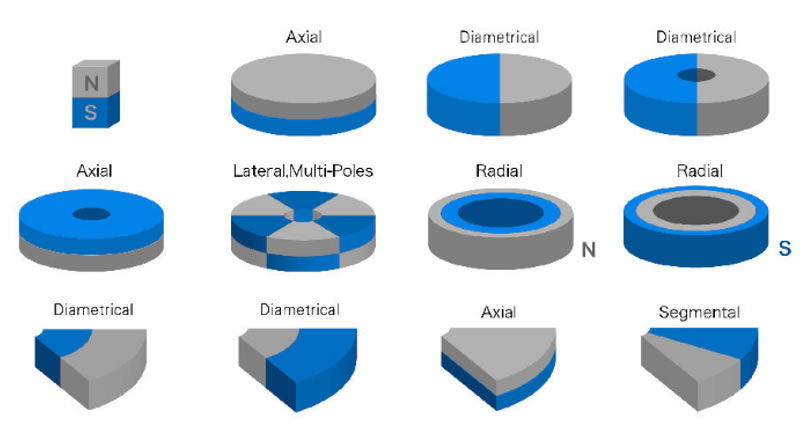

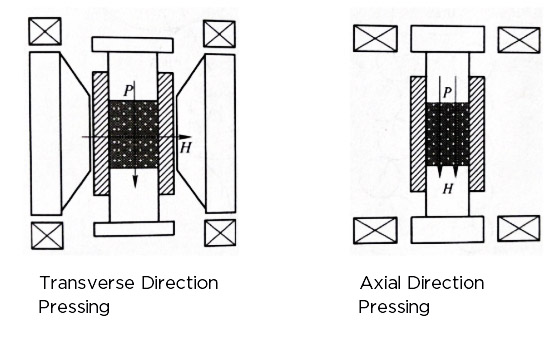

The orientation forming of Neodymium Magnets involves aligning the easy magnetization direction of Nd-Fe-B alloy powder with the magnet’s final magnetization direction. This is achieved through the interaction of magnetic powder with an external magnetic field, typically above 0.8A/m. In the industrial production, pressing is categorized mainly into single and double pressing methods:

- Single Pressing: Uses a uniaxial press (50-100MPa pressure, resulting in a pressed density of 55%-60% of the real density) or cold isostatic press (200MPa pressure, achieving about 60% real density).

- Double Pressing: Combines uniaxial pressing (20-30MPa pressure, 45% real density) followed by cold isostatic pressing (200MPa, reaching about 60% real density).

During forming, magnetic powder particles retain their c-axis alignment. Demagnetization follows to eliminate magnetic interactions that can disrupt particle orientation. Pressures up to 100 MPa are used, balancing mechanical and magnetic forces to maintain orientation.

The powder’s orientation degree is also influenced by internal friction. Organic lubricants are used to reduce this friction but must be completely removed before sintering (typically around 200℃) to prevent oxidation or carbonization, which can degrade magnet performance.

Three common forming processes are:

- Transverse Direction Pressing (TDP)

- Axial Direction Pressing (ADP)

- Isostatic Pressing (IP), with variants like Rubber Isostatic Pressing (RIP)

The Science Behind Magnetic Alignment

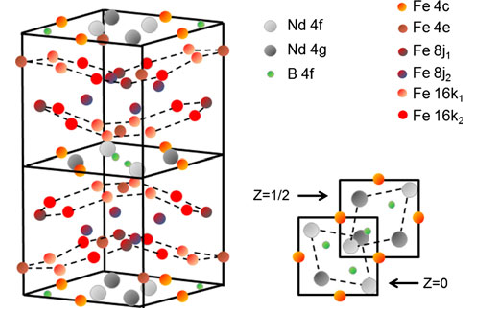

Magnetic alignment in Neodymium Magnets hinges on magnetocrystalline anisotropy, a key concept in material science. NdFeB alloys, when crushed into single crystal grains, showcase single-axis anisotropy. Each grain has a preferred magnetization direction, typically along the crystal’s c-axis. The orientation forming process involves applying an external magnetic field to align these axes in the desired direction, a critical factor in enhancing the magnet’s performance.

The effectiveness of this alignment is influenced by several factors:

- Strength of the Applied Magnetic Field: The field must be strong enough to overcome the random orientation of particles and align them uniformly.

- Particle Size and Shape: Smaller particles are more easily aligned, and their shape can influence the efficiency of alignment.

- Degree of Alignment during Pressing: The uniformity of the alignment directly affects the magnet’s strength and directionality.

Perfect alignment is challenging to achieve, and even minor deviations can significantly impact the magnet’s efficiency. The interplay of these factors determines the magnet’s final magnetic properties, with the aim always being to maximize magnetic strength and directionality for its intended use. This meticulous alignment process is what enables Neodymium Magnets to have strong and uniform magnetic fields, making them essential in various high-performance applications.

Challenges and Innovations in Magnet Production

The production of Neodymium Magnets is not without its challenges. Each stage of the process, from initial alloy formation to the final magnetization, must be meticulously controlled to ensure the highest quality and performance. Here are some of the key challenges and innovations in the field:

- Particle Movement and Alignment: During the pressing process, high pressures of up to 100 MPa are required. This immense pressure can cause the magnetic particles to move or rotate, potentially misaligning them from the desired orientation. This misalignment can significantly reduce the magnet’s overall performance. To address this, manufacturers balance the magnetic field strength and forming pressure to maximize alignment while minimizing particle displacement.

- Internal Friction: The orientation of the powder is also affected by internal friction within the powder itself. This is especially pronounced when the loose packing density is high. To reduce this internal friction, organic lubricants are used during the manufacturing process. However, these lubricants must be completely removed before sintering (usually around 200°C) to avoid oxidation or carbonization, which could degrade the magnet’s performance.

- Innovations in Pressing Techniques: There are continuous advancements in pressing techniques to improve the efficiency and effectiveness of the alignment process. The development of more sophisticated presses and techniques, such as improved Isostatic Pressing methods, has led to more uniform and higher-quality magnets.

- Advancements in Material Science: The ongoing research in material science, including the development of new alloys and treatment processes, has significantly enhanced the properties of Neodymium Magnets. Innovations in grain boundary diffusion and the manipulation of microcrystalline structures are examples of how material science is pushing the boundaries of what is possible in magnet production.

These challenges are met with a blend of precision engineering, material science innovations, and continual process improvements. As a result, Neodymium Magnets continue to evolve, offering higher performance and new applications across various industries.

Conclusion

As we conclude this third installment of our Neodymium Magnet Production Series, we’ve explored the intricate and highly technical processes of orientation and shaping. These stages are pivotal in determining the final performance of the magnets, impacting their strength and utility in various applications.

We’ve seen how the alignment of magnetic particles, challenges of internal friction, and innovations in pressing techniques contribute to the production of high-quality Neodymium Magnets. The balance between mechanical force and magnetic alignment, alongside the advancements in material science, underlines the complexity and precision required in magnet production.

Looking ahead, our next part in the series, Neodymium Magnet Production Series: Part 4 – Sintering, Heat Treatment, and Machining, will delve deeper into the subsequent stages of Neodymium Magnet production. These processes are equally critical, as they enhance the magnet’s magnetic properties and ensure its durability and suitability for specific applications.

Stay tuned as we continue to unravel the fascinating journey of Neodymium Magnet production, showcasing the blend of science and engineering that makes these powerful magnets a cornerstone of modern technology.