At EPI Magnets, we’re not just suppliers, we’re experts dedicated to understanding every facet of the magnetic materials we work with. Today, we delve deep into the physical properties of sintered Neodymium-Iron-Boron (NdFeB) magnets, a critical functional component in a wide array of equipment including motors, acoustic devices, magnetic assemblies, and sensors.

Throughout their lifecycle, these magnets face a barrage of environmental factors – from mechanical stresses to thermal fluctuations, and the relentless push and pull of alternating electromagnetic fields. Any environmental failure can drastically compromise equipment functionality, leading to significant operational and financial setbacks. It’s not just about magnetic indices; understanding the mechanical, thermal, and electrical attributes of these magnets is pivotal for their optimal design, application, and enhancement of service stability and reliability.

Mechanical Properties: The Strengths and Brittle Truths

The mechanical resilience of NdFeB magnets is quantified through various indicators, including hardness, compressive strength, bending strength, tensile strength, impact toughness, and Young’s modulus. Characteristically brittle, these magnets boast high hardness and compressive strength. However, they fall short in bending strength, tensile strength, and impact resilience, making them prone to chipping or even fracturing during processes like machining, magnetization, or assembly. Typically, these magnets are secured within devices using grooves or adhesives and are cushioned with shock-absorbing materials to prevent damage.

Test Item | Typical Values | Testing Equipment |

Hardness | 550-700 | Vickers Hardness Tester |

Compressive Strength | 800-1100 MPa | Compression Testing Machine or Universal Testing Machine |

Bending Strength | 200-400 MPa | Various Universal Testing Machines and Pressure Testing Machines |

Tensile Strength | 60-100 MPa | Tensile Strength Tester or Universal Testing Machine |

Impact Toughness | 27-47 kJ/m² | Pendulum Impact Tester |

Young’s Modulus | 150-180 Gpa | Young’s Modulus Tester or Universal Testing Machine |

Delving deeper into their composition reveals that the fracture surfaces of sintered NdFeB are typically characterized by intergranular fracturing. Their mechanical properties are largely determined by their complex multiphase structures and are also intricately linked to the composition of the materials, processing parameters, and structural defects such as pores, large grains, and dislocations. Generally, a lower total amount of rare earth elements correlates with poorer mechanical performance.

Enhancing the toughness of magnetic steel is possible through the strategic addition of metals. Introducing moderate amounts of low-melting-point metals like Copper (Cu) and Gallium (Ga) improves the distribution of grain boundary phases, thereby enhancing the magnet’s toughness. Conversely, incorporating high-melting-point metals such as Zirconium (Zr), Niobium (Nb), and Titanium (Ti) leads to the formation of precipitate phases at the grain boundaries. This not only refines the grain and helps inhibit crack propagation, thereby improving strength and toughness, but also requires maintaining a delicate balance. Excessive additions can significantly increase the material’s hardness, adversely impacting processing efficiency.

In practical manufacturing scenarios, achieving the perfect balance between the magnetic and mechanical properties of magnetic materials is challenging. Constraints related to cost and performance requirements often necessitate compromises, typically at the expense of ease of processing and assembly.

Thermal Properties: Handling the Heat

The main thermal performance indexes of Neodymium magnets include thermal conductivity, specific heat capacity and thermal expansion coefficient.

Test Item | Typical Values | Testing Equipment |

Thermal Conductivity | 8-10 W/(m·K) | Thermal Conductivity Tester |

Specific Heat Capacity | 3.5~6.0 J/(kg·K) | Laser Flash Apparatus |

Coefficient of Thermal Expansion | 4-9×10^6/K (CIl) -2-0x10^6/K (C⊥) | Dilatometer (Pushrod Type) |

The performance of NdFeB magnets is intrinsically linked to temperature, with their capabilities diminishing as temperatures rise. This thermal sensitivity makes the temperature elevation within permanent magnet motors a critical factor determining whether the motor can sustain long-term operational loads. To prevent overheating and ensure the continuous, reliable operation of equipment, magnets need to possess excellent heat conduction and dissipation abilities. This is where a high thermal conductivity and specific heat capacity become desirable traits, allowing for the rapid transmission and dispersion of heat, and consequently, a lower temperature rise under the same heat conditions.

However, the behavior of Neodymium magnets under heat is not so straightforward due to their unique thermal expansion characteristics. These magnets are easily magnetized in a specific direction (parallel to the C-axis), and in this orientation, they expand when heated. Intriguingly, in the two directions difficult to magnetize (perpendicular to the C-axis), the magnets exhibit negative thermal expansion, meaning they contract when heated. This anisotropy in thermal expansion not only makes ring-shaped magnets prone to cracking during the sintering process but also poses challenges in permanent magnet motors. Typically, these motors use a framework of soft magnetic material to support the magnet, and the differing thermal expansion properties between the two materials can affect their dimensional compatibility post-temperature elevation.

Understanding and mitigating these thermal challenges are crucial for maintaining the integrity and performance of Neodymium magnets in practical applications. At EPI Magnets, we continuously explore innovative solutions to enhance the thermal properties of our magnets, ensuring they meet the rigorous demands of modern applications.

Electrical Properties: Contending with Eddy Currents

In the dynamic environment of a rotating permanent magnet motor, NdFeB magnets are subjected to alternating electromagnetic fields, a scenario that gives rise to the phenomenon of eddy currents within the magnets. These eddy currents are particularly troublesome as they generate heat, leading to an increase in the magnet’s temperature. Given that eddy current losses are inversely proportional to resistivity, one solution to mitigate these losses – and the consequent thermal challenges – is to enhance the resistivity of the NdFeB magnets themselves.

Test Item | Typical Values | Testing Equipment |

Electrical Resistivity | 1.2-1.6 μΩ*m | Kelvin Double-bridge Resistivity Meter |

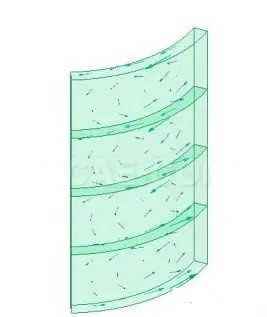

The ideal high-resistivity magnetic structure is one that impedes electron flow, achieved by elevating the electrode potential of the rich rare-earth phase. This creates an insulating barrier layer that effectively separates the main phase grains, resulting in a significant increase in the resistivity of the sintered NdFeB magnet. However, current methods, whether through the doping of inorganic materials or layering techniques, struggle to overcome a fundamental hurdle: the deterioration of magnetic properties. As of now, there’s no effective means to produce a magnet that possesses both high resistivity and high-performance magnetic properties.

This challenge underscores a critical trade-off in magnet design and emphasizes the need for innovative solutions in the manufacturing process. At EPI Magnets, we’re dedicated to pioneering research and development efforts to push the boundaries of what’s possible in magnetic material technology.

Balancing the magnetic, mechanical, thermal, and electrical properties in NdFeB magnets is a nuanced process, often requiring trade-offs between manufacturability and performance due to cost constraints and specific performance requisites.

At EPI Magnets, we’re committed to pushing the boundaries of what’s possible with magnetic materials. Stay tuned to our blog for more insights and deep dives into the fascinating world of magnets!