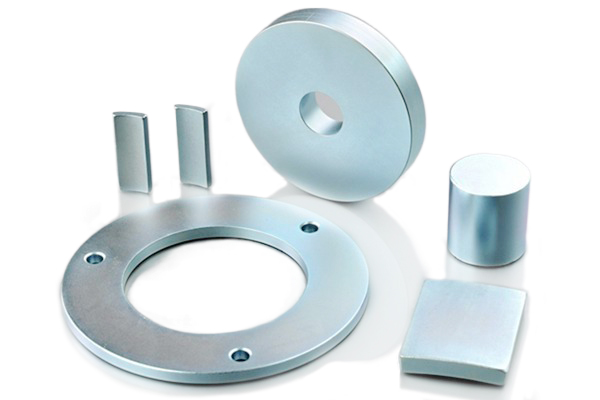

Neodymium Iron Boron (NdFeB) magnets necessitate the use of a protective layer or surface treatment to guard against potential damage from corrosion.

Exposure to atmospheric moisture alone can lead to signs of corrosion in an uncoated NdFeB magnet. Moreover, these magnets are exceptionally susceptible to corrosion in marine environments. Corrosion in these magnets, akin to rusting, results in an irreversible alteration of their structure. This leads to a gradual decline in their magnetic capabilities, causing the magnet to weaken over time. During the corrosion process, the magnet can also disintegrate into a powdery substance. In extreme cases, corrosion can lead to a complete loss of magnetic functionality. Hence, it’s imperative to apply a protective coating or surface finish to these magnets.

There’s a wide range of surface finishes to choose from, and the choice can be influenced by the specific application of the magnet. For instance, gold plating is chemically inert due to its noble nature, making it an ideal choice for many medical uses. On the other hand, a rubber coating can provide extra friction and may be preferred in certain contexts.

Different level of preventing corrosion: Superior > Excellent > Acceptable > Bad

| PLATING / COATING | THICKNESS | INDOOR USE | ABRASION RESISTANCE | HUMIDITY | WATER | SALTY AIR | SALT WATER | GLUE | PRICE |

|---|---|---|---|---|---|---|---|---|---|

| Nickel (Ni-Cu-Ni) | 10-20 Microns | Excellent | Acceptable | Acceptable | Bad | Bad | Bad | Bad | Low |

| Zinc (Zn) | 8-10 Microns | Excellent | Excellent | Excellent | Acceptable | Acceptable | Bad | Acceptable | Low |

| Gold (Ni-Cu-Au) | 10-20 Microns | Excellent | Acceptable | Acceptable | Bad | Bad | Bad | Bad | High |

| Epoxy | 10-20 Microns | Superior | Acceptable | Superior | Superior | Excellent | Excellent | Superior | Medium |

| Ni-Cu-Epoxy | 15-25 Microns | Superior | Bad | Superior | Superior | Excellent | Excellent | Acceptable | Medium |

| Plastic | >800 Microns | Superior | Superior | Superior | Superior | Superior | Superior | Excellent | High |

| Teflon® (PTFE) | 4 mm | Superior | Superior | Superior | Superior | Superior | Superior | Bad | High |

| Xylan® (PTFE) | 20-30 Microns | Superior | Superior | Superior | Superior | Superior | Superior | Bad | High |

| Everlube-6155® | 8-25 Microns | Superior | Superior | Superior | Superior | Superior | Superior | Acceptable | High |

Nickel (Ni-Cu-Ni)

The Ni-Cu-Ni coating, a triple-layered plating consisting of nickel, copper, and nickel, is widely recognized for its durability and versatility. This coating provides exceptional value for money, displaying remarkable resistance to humid and hot conditions, and excellent adhesion properties.

This plating is predominantly used in a vast array of applications, owing to its adaptability to most environments. It is particularly prevalent in industrial permanent magnet motors, thanks to its dependable performance. While it’s an excellent choice for indoor usage, the Ni-Cu-Ni coating can also be employed outdoors, provided it’s safeguarded from moisture and rainfall. Another key advantage of this plating is its robust abrasion resistance, further enhancing its durability and lifespan.

Zinc (Zn)

Zinc (Zn) plating stands as a cost-effective solution, offering standard protective capabilities. This standalone, single-layer coating is particularly unique due to its self-sacrificing property. When zinc starts to oxidize, it turns white, forming a resilient protective layer, which further enhances its durability.

This coating is well-suited for applications that require standard protection but are also sensitive to costs. Industrial motors and power tools are typical examples of where Zinc plating finds its application. Its affordability coupled with its adequate protective feature makes Zinc plating an attractive choice in many industries.

Gold (Ni-Cu-Au)

The Gold (Ni-Cu-Au) coating for Neodymium Iron Boron magnets offers a distinctive blend of functionality and aesthetics. This thin, cosmetic layer of gold, often applied over an underlayer of nickel, not only enhances the magnet’s visual appeal but also provides a brighter finish.

One of the prime benefits of this coating is its excellent resistance to salt fog, making it a durable choice for various applications. Beyond its protective qualities, the Gold (Ni-Cu-Au) coating is also lauded for its attractive appearance.

This combination of durability and elegance makes it an ideal choice for high-end applications, particularly those where aesthetics play a vital role. It’s commonly used in luxury items such as jewelry boxes, trinket boxes, and premium cosmetic containers, where both the protective and aesthetic properties of the Gold (Ni-Cu-Au) coating can be fully utilized.

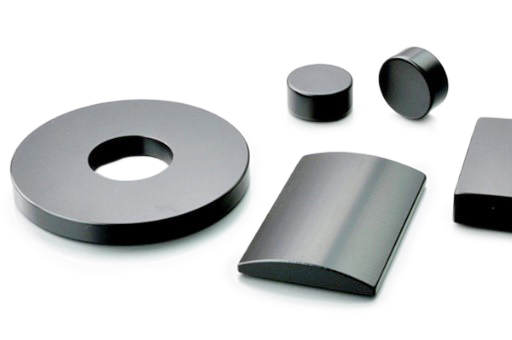

Epoxy

The Epoxy coating serves as an exceptional solution for Neodymium magnets, primarily known for its excellent resistance to humidity, heat, and adhesion performance. This single-layer coating is designed specifically for instances where the magnet requires robust adhesion to epoxy glue.

A unique advantage of the Epoxy coating is its superior resilience to humid and salty conditions. This makes it perfectly suited for applications demanding high resistance to such environments, including offshore wind turbines and rail traction motors, among others.

In essence, the Epoxy coating provides not only a protective shield against challenging conditions but also ensures a strong bond with epoxy glue, making it a go-to choice for many demanding industrial applications.

Ni-Cu-Epoxy

The Ni-Cu-Epoxy coating represents an innovative solution for Neodymium Iron Boron magnets, offering enhanced protection and resilience. This three-layered coating, composed of nickel, copper, and epoxy, offers a unique combination of benefits.

The initial layers of nickel and copper provide a strong foundation, offering good adhesion and resistance to various environmental conditions. The outer layer of epoxy then enhances these protective qualities, granting excellent resistance to both humidity and heat.

This multilayered coating is known for its durability and robustness, making it an excellent choice for a variety of applications. Whether the need is for enhanced environmental resistance or improved adhesion for gluing applications, the Ni-Cu-Epoxy coating provides a reliable and versatile solution.

Plastic

The Plastic coating for Neodymium Iron Boron magnets offers a robust protective layer, safeguarding the magnet from chipping, corrosion, and water damage. This results in remarkable water-resistant and damage-proof performance, making Plastic coated magnets ideal for various applications, including aquariums, marine environments, construction sites, and outdoor settings. In more severe operating conditions, such as acidic or alkaline environments, PTFE Coated Magnets are recommended.

In addition to its protective features, the Plastic coating also provides enhanced friction, enabling the coated magnets to exhibit superior slip resistance in various holding applications. When applied to a metal surface, the coating helps prevent scratching on the contact surfaces, further demonstrating its versatility.

Some Plastic-coated mounting magnets are designed with a central threaded hole or a central threaded stud to facilitate attachment using bolts, hooks, or eye bolts. Others feature pre-drilled holes for easy installation using screws or nails. The plastic coating not only prevents corrosion and chipping but also safeguards the mounting surface from damage, while the high friction of the coating delivers improved holding force on vertical surfaces.

Teflon® (PTFE)

EPI’s Teflon coating for Neodymium Iron Boron magnets is a testament to the power of high-performance materials. Leveraging Teflon materials purchased from DuPont, this coating provides a thick, 4mm layer that imparts exceptional corrosion resistance. This enables the magnets to withstand strong acid or alkali environments.

Nevertheless, the thickness of the Teflon coating does come with certain considerations. It limits the dimensions of the inner magnets and can diminish the pull force and overall magnetic capabilities. For instance, a final product with dimensions of 20mm diameter and 18mm thickness would have inner magnets measuring only 12mm in diameter and 10mm in thickness.

These factors should be taken into account during the design and Request for Quotation (RFQ) stages. Feel free to contact us or send your RFQ or drawings via email to Sales@epimagnets.com.

If the reduction in magnetic performance due to the thickness of the Teflon coating is a concern, we highly recommend our Xylan coated Magnets. These offer a similar level of protection but with a significantly thinner coating of only 20 to 30 microns.

Xylan® (PTFE)

EPI’s Xylan coating for Neodymium Iron Boron magnets utilizes high-performance materials sourced from Whitford, a trusted industry name. Our most commonly used Xylan coating is the 1424 grade, which boasts a thin layer of only 20 to 30 microns. Despite its thinness, it delivers excellent corrosion resistance with a Salt Spray Test (SST) result of 300-400 hours, substantially outperforming the standard 72-hour SST result of NiCuNi coating.

To further enhance corrosion resistance, EPI offers a double Xylan coating option. This entails an initial base layer of Xylar2 coating, topped with a layer of Xylan 1424. The combined thickness of this double coating measures between 40 to 50 microns, offering a robust protective layer without significantly impacting the magnet’s performance.

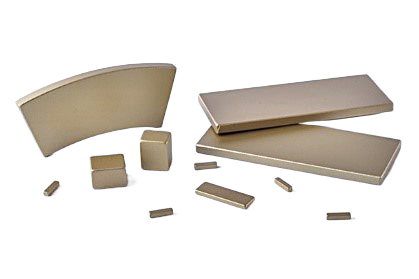

Everlube

EPI’s Everlube coating for Neodymium Iron Boron magnets is a specially formulated aluminized barrier coating designed to enhance adhesion and corrosion protection. This coating is particularly robust, providing outstanding chemical and corrosion resistance, even in challenging environments.

One of the hallmarks of Everlube coating is its exceptional resistance to humid and high-temperature conditions. This makes it particularly suitable for applications where durability under such conditions is a requirement. For instance, automotive parts, some of which are expected to last over 15 years, greatly benefit from the longevity offered by Everlube coating.

In addition, Everlube’s high adhesive properties make it widely used in industrial permanent motors and frequency conversion compressors among other applications. Offering an excellent blend of resilience and performance, Everlube coating is the ideal choice for applications demanding superior longevity and resistance to extreme conditions.