Neodymium mounting magnets are neodymium magnets mounted in steel cups or slots. They are therefore also known as “Pot magnets” or “Cup magnets”. The most common shape of the mounting magnets is round, but we also offer the ones in rectangular.

The basic construction of the mounting magnets consists of neodymium magnets, steel shells and spacers. The mounting magnets could be produced with several mounting options including countersunk holes, threads mounted with nuts, bolts and various hooks.

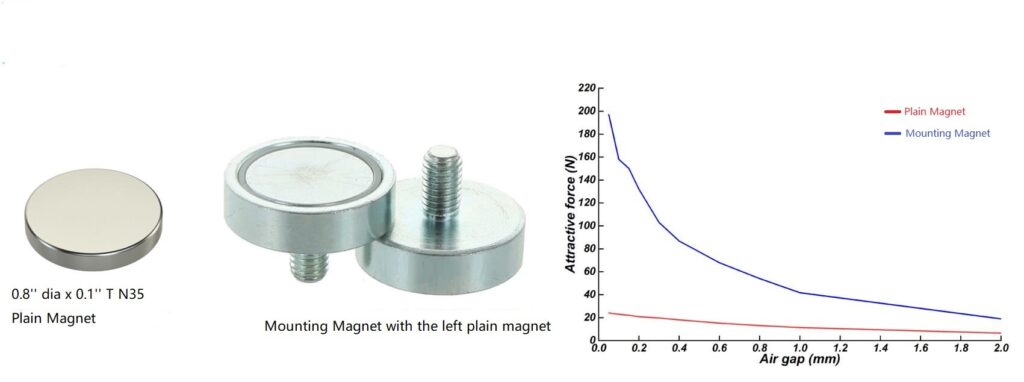

Compared to a plain magnet in the mounting magnets, the fully assembled magnets offer twice the pull force.

The pull force of a magnet is positively related to the size of the magnet itself. If using a plain magnet, the size has to be bigger and thus the cost gets higher. Comparatively, the mounting magnets offer either the same pull force at a lower cost or a stronger force at the same cost.

Why Mounting Magnets offer stronger force?

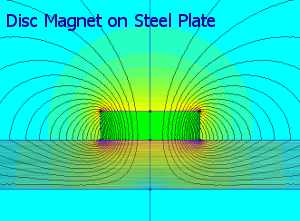

Normally, the magnetic induction lines of a plain magnet are freely distributed in the air. The following picture shows the distribution of the magnetic field of an plain disc magnet attracted to a steel plate. At the contact surface between the magnet and the steel plate, a strong attractive force is created. But the magnetic field generated on the opposite side does not contribute much to this force.

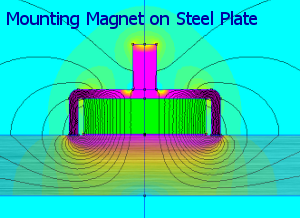

For Mounting Magnet, the Neodymium magnets are set inside a steel shell. The magnetic permeability of the steel shell is much greater than that of air, leading to the redistribution of the magnetic field from the opposite side and concentrate the flux from both magnetic poles to one active face. As shown in the diagram below, the magnetic field strength at the contact surface between the mounting magnet and the steel plate has been greatly enhanced.

Neodymium magnets are made by powder metallurgy and they are a hard and fragile material. If they hit each other or hit a steel surface, they will shatter or break. The construction of the mounting magnets provides excellent protection for the magnets.

Our magnets are available in a wide range of mounting options and in metric (millimeters) and standard (inches) styles.

Here list our standard products. For any custom sizes, grade or coating/plating specifications, please contact us directly to get a quote.

| EPI Product ID | EPI-MM-A-16 |

|---|---|

| Dimensions | D=16mm (0.63″) d1=3.5mm (0.14″) (Sized for M3 screw) d2=6.5mm (0.26″) (Tapered countersunk hole) h=5mm (0.20″) |

| Tolerances | All ±0.004″ |

| Grade | N38 |

| Plating/Coating | Ni-Cu-Ni (Nickel) |

| Magnetization Direction | Axial (Poles on Flat Ends) |

| Pull Force | 11.00 lbs |

| EPI Product ID | EPI-MM-A-20 |

|---|---|

| Dimensions | D=20mm (0.79″) d1=4.5mm (0.18″) (Sized for M4 screw) d2=8.5mm (0.33″) (Tapered countersunk hole) h=7mm (0.28″) |

| Tolerances | All ±0.004″ |

| Grade | N38 |

| Plating/Coating | Ni-Cu-Ni (Nickel) |

| Magnetization Direction | Axial (Poles on Flat Ends) |

| Pull Force | 16.20 lbs |

| EPI Product ID | EPI-MM-A-25 |

|---|---|

| Dimensions | D=25mm (0.98″) d1=5.5mm (0.22″) (Sized for M5 screw) d2=10mm (0.39″) (Tapered countersunk hole) h=8mm (0.32″) |

| Tolerances | All ±0.004″ |

| Grade | N38 |

| Plating/Coating | Ni-Cu-Ni (Nickel) |

| Magnetization Direction | Axial (Poles on Flat Ends) |

| Pull Force | 31.00 lbs |

| EPI Product ID | EPI-MM-A-32 |

|---|---|

| Dimensions | D=32mm (1.26″) d1=5.5mm (0.22″) (Sized for M5 screw) d2=10mm (0.39″) (Tapered countersunk hole) h=8mm (0.32″) |

| Tolerances | All ±0.004″ |

| Grade | N38 |

| Plating/Coating | Ni-Cu-Ni (Nickel) |

| Magnetization Direction | Axial (Poles on Flat Ends) |

| Pull Force | 55.1 lbs |

| EPI Product ID | EPI-MM-A-36 |

|---|---|

| Dimensions | D=36mm (1.42″) d1=6.5mm (0.26″) (Sized for M6 screw) d2=12mm (0.47″) (Tapered countersunk hole) h=8mm (0.31″) |

| Tolerances | All ±0.004″ |

| Grade | N38 |

| Plating/Coating | Ni-Cu-Ni (Nickel) |

| Magnetization Direction | Axial (Poles on Flat Ends) |

| Pull Force | 63.9 lbs |

| EPI Product ID | EPI-MM-A-42 |

|---|---|

| Dimensions | D=42mm (1.65″) d1=6.5mm (0.26″) (Sized for M6 screw) d2=12.5mm (0.49″) (Tapered countersunk hole) h=9mm (0.35″) |

| Tolerances | All ±0.004″ |

| Grade | N38 |

| Plating/Coating | Ni-Cu-Ni (Nickel) |

| Magnetization Direction | Axial (Poles on Flat Ends) |

| Pull Force | 81.6 lbs |

We will contact you within 1 working day. You can also contact us by sending emails directly to sales@epimagnets.com.

We will contact you within 1 working day. You can also contact us by sending emails directly to sales@epimagnets.com.