A magnetic coupling is a non-contact coupling that usually consists of two magnetic hubs (usually a pair of discs with magnets – Disc Type, or two magnetic inner rotors and outer rotors – Coaxial Type). One of the magnetic hubs is connected to the driving part and the other is connected to the driven part. The magnetic field transfers the torque from the driving part of the coupling to the driven part. Without any physical contact, the torque is transmitted via the gap air or non-magnetic sealing barrier (such as stainless steel or fiberglass). The two magnetic hubs are completely isolated. This is the greatest advantage of magnetic couplings over other mechanical couplings: contactless transmission of torque, thus transforming a dynamic seal into a static seal and achieving zero leakage.

Due to non-contact and leak-free torque transmission in magnetic drive pumps and magnetic stirrers, magnetic coupling is widely used in applications with highly toxic or corrosive mediums where sealing drives are essential to prevent harmful mediums from leaking. As an experienced leading supplier, EPI Magnets provides a wide range of custom magnetic couplings from single products to whole solutions.

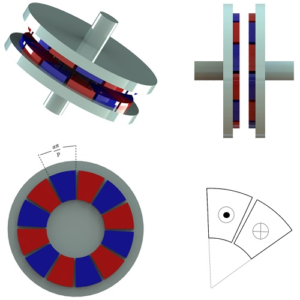

The Disc Type Magnetic Coupling has two face-to-face discs with a series of Neodymium magnets (or SmCo magnets) and the torque is transmitted from one disc to the other through an air gap. The design is so simple that even with angular misalignment up to 3° or parallel misalignment up to 1/4”, it can still transmit rotational torque almost without loss. A plain non-magnetic barrier can isolate the atmosphere or liquid medium around the two discs. This is the simplest magnetic coupling to design and manufacture.

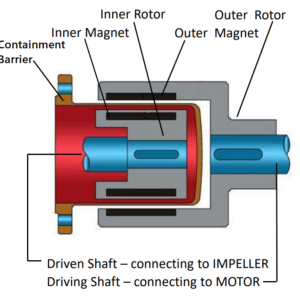

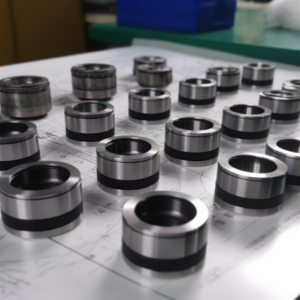

A Coaxial Type Magnetic Coupling generally consists of an inner hub, an outer hub, and an optional sealing barrier. The inner and outer hubs are the rotors attached with Neodymium magnets (or SmCo magnets). The driven shaft of the inner rotor is connected to the driven devices such as impellers, and the driving shaft of the outer rotor is connected to the motors. Through Coaxial Type magnetic couplings, the force of the motor is transferred to the impeller without direct contact: The inner rotor revolves in synchrony with the outer rotor thanks to the magnetic force that transfers the torque from the motor to the inner rotor. Lastly, the impeller is made to rotate by the inner rotor.

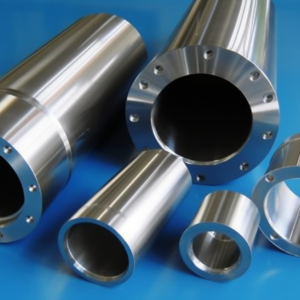

The sealing barrier seals the inner rotor and the medium inside the pump to prevent the toxic or corrosive medium from flowing out of the pump. Depending on the type of the medium, the inner rotor needs to be sealed inside a sealing barrier of different materials to protect the inner rotor from damage. Carbon steel, stainless steel, or plastic(PTFE, PFA, TFM, PVDF) are frequently used for inner rotor construction. Materials used as common sealing barriers include titanium, plastic(PTFE, PFA, TFM, PVDF), stainless steel, and Hastelloy. Since the outer rotor typically operates in a typical working environment without any particular chemical requirements, carbon steel and other less expensive materials are frequently used. The material to be used depends on the environment and medium to which the magnetic coupling will be subjected determine, hence it is important for our customers to provide specific usage conditions or requirements.

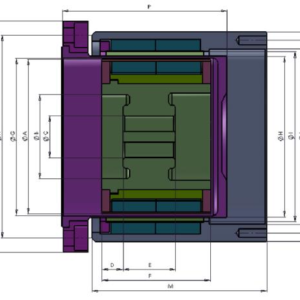

| Type | Nom. Torque | Over Load | Inner Rotor (mm) | Outer Rotor (mm) | Sealing can/Flange (mm) | |||||||||||||

| A | B | C | D | E | F | I | J | K | L | M | G | H | N | O | P | |||

| EPICC03 | 3 | 4.5 | 42 | 20 | 10 | 5 | 15 | 25 | 49 | 52 | M5 | 68 | 50 | 44 | 46 | 6.6 | 80 | 57 |

| EPICC08 | 8 | 12 | 58 | 26 | 12 | 10 | 18 | 35 | 66 | 70 | M5 | 90 | 65 | 60 | 62 | 6.6 | 96 | 67 |

| EPICC16 | 16 | 26 | 58 | 26 | 14 | 30 | 20 | 62 | 66 | 70 | M6 | 90 | 95 | 60 | 62 | 6.6 | 96 | 94 |

| EPICC22 | 22 | 35 | 88 | 50 | 20 | 10 | 30 | 50 | 97 | 100 | M6 | 120 | 85 | 90 | 92 | 8.6 | 132 | 82 |

| EPICC30 | 30 | 48 | 88 | 50 | 24 | 20 | 30 | 62 | 97 | 100 | M6 | 120 | 100 | 90 | 92 | 8.6 | 132 | 94 |

| EPICC50 | 50 | 80 | 122 | 80 | 30 | 10 | 30 | 60 | 132 | 136 | M8 | 164 | 85 | 126 | 128 | 8.6 | 176 | 88 |

| EPICC65 | 65 | 100 | 122 | 80 | 30 | 20 | 30 | 65 | 132 | 136 | M8 | 164 | 100 | 126 | 128 | 8.6 | 176 | 104 |

| EPICC80 | 80 | 130 | 142 | 90 | 35 | 20 | 30 | 65 | 152 | 156 | M8 | 184 | 100 | 146 | 148 | 10.8 | 208 | 106 |

| EPICC110 | 110 | 165 | 142 | 90 | 35 | 30 | 30 | 80 | 152 | 156 | M8 | 184 | 115 | 146 | 148 | 10.8 | 208 | 122 |

| EPICC140 | 140 | 210 | 142 | 90 | 40 | 40 | 40 | 110 | 152 | 156 | M10 | 190 | 145 | 146 | 148 | 10.8 | 208 | 152 |

| EPICC180 | 180 | 290 | 142 | 90 | 40 | 60 | 50 | 140 | 152 | 156 | M10 | 190 | 180 | 146 | 148 | 10.8 | 208 | 182 |

| EPICC220 | 220 | 330 | 142 | 90 | 48 | 70 | 60 | 160 | 152 | 156 | M10 | 190 | 200 | 146 | 148 | 10.8 | 208 | 204 |

| EPICC280 | 280 | 380 | 142 | 90 | 48 | 90 | 60 | 180 | 152 | 156 | M10 | 190 | 230 | 146 | 148 | 10.8 | 208 | 224 |

| EPICC320 | 320 | 430 | 164 | 110 | 50 | 90 | 60 | 190 | 174 | 178 | M12 | 214 | 230 | 168 | 170 | 10.8 | 230 | 240 |

| EPICC380 | 380 | 500 | 164 | 110 | 50 | 100 | 80 | 240 | 174 | 178 | M12 | 214 | 280 | 168 | 170 | 10.8 | 230 | 290 |

| EPICC500 | 500 | 650 | 186 | 130 | 60 | 115 | 90 | 300 | 196 | 190 | M12 | 240 | 300 | 190 | 192 | 10.8 | 250 | 310 |

We will contact you within 1 working day. You can also contact us by sending emails directly to sales@epimagnets.com.