Magnetic rotor assemblies are essential for high-performance equipment and systems in various industries, including aerospace, oil & gas, and motor-dependent applications.

At EPI Magnets, our ability to manufacture and design our magnetic materials and assemblies in-house allows us to offer personalized solutions and modify magnetic fields to meet your specific requirements. We utilize the most advanced assembly technologies to ensure reliable and long-lasting performance, including super gluing strength, high-temperature endurance of glue, elimination of eddy currents, and surface protection. Our engineering team is committed to working closely with our customers to optimize magnetic flux and tailor our products to your unique needs.

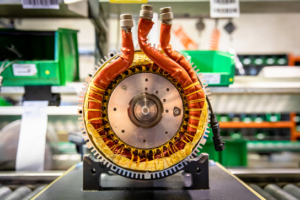

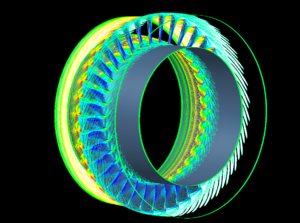

EPI Magnetic Rotors are designed to operate under the most demanding conditions, utilizing state-of-the-art assembly technologies. These include superior adhesive strength, high-temperature resistant glues, eddy current elimination, and advanced surface protection. We showcase a variety of magnetic rotor types, each demonstrating how these technologies are applied to suit different applications and conditions. Our engineering team is committed to working closely with our customers to optimize magnetic flux for the best possible performance.

Motor manufacturers are continuously striving to enhance performance and reduce costs, delivering greater value to their customers. Permanent magnet rotor assemblies are essential for optimizing performance in modern electrical motors. EPI Magnets’ engineering team has extensive experience in designing high-quality rotor assemblies for a variety of demanding applications, such as high-speed motors, high-temperature motors, space exploration, downhole exploration, and implantable medical devices.

We consider the following key factors when working with customers on their rotor designs:

Our engineering team understands the intricacies of permanent magnet materials, enabling us to guide customers in selecting the best material for their specific application. We also have the capability to develop custom grades of permanent magnet material to meet unique requirements.

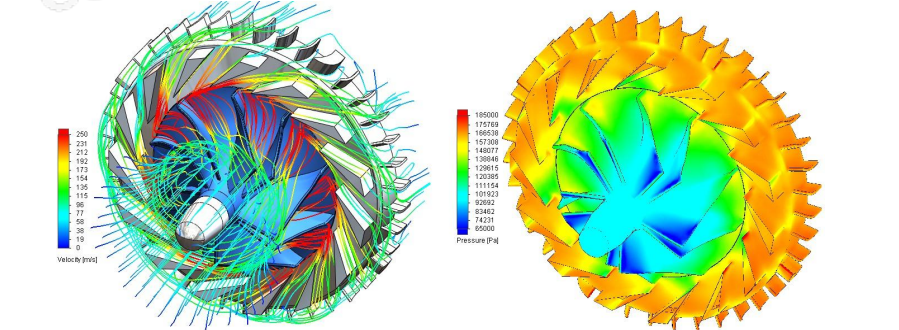

Our engineers collaborate with customers to optimize component designs for manufacturing, ultimately enhancing performance and reducing costs. We provide valuable input on magnet component designs, shaft designs, sleeving options, and overall rotor packaging to help customers maximize their motor designs.

Choosing the appropriate bonding and sleeving materials is crucial for ensuring reliable rotor performance. We advise customers on the best adhesives to use based on retention and temperature requirements. For high-speed motor applications, we help customers select the optimal metallic or composite sleeving material.

Many applications require rotors to be balanced for optimized performance within the electric motor system. We offer balancing services and can customize final inspection tests to meet each customer’s unique requirements, going beyond our standard testing procedures.

We provide an extensive variety of permanent magnet types, including neodymium iron boron, samarium cobalt, alnico, and ceramic, to accommodate nearly any application requirement. Our in-house Material Technical Center ensures customers have access to a diverse selection of products that can be customized efficiently and affordably.

Our dedicated R&D lab, an exceptional team of scientists and engineers, and collaborative partnerships with universities empower us to deliver pioneering magnet solutions for applications in medical, aerospace, and other industries. We cater to both government and commercial sectors, providing state-of-the-art technology and unrivaled expertise.

Our engineers utilize finite element analysis (FEA) to help customers with magnetic circuit design and optimization. Our engineering experts can offer innovative magnetic circuit design solutions for even the most challenging applications, reducing costs and improving system performance.

Our integrated production process guarantees that our engineers possess a comprehensive understanding of magnets and magnet assembly processes. This knowledge not only results in superior products but also accelerates time-to-market by minimizing costly mistakes. We offer complete before and after engineering support, ensuring expert assistance is always within reach.

In a rapidly changing industry landscape, efficient product development is crucial. We support customers in achieving their objectives by providing quick, dependable, and cost-effective proof-of-concept prototypes and product evaluations within a short timeframe.

We will contact you within 1 working day. You can also contact us by sending emails directly to sales@epimagnets.com.