PTFE is short for Polytetrafluoroethylene which is a fluoropolymer. PTFE Coated Neodymium Magnet is the NdFeB magnet that is covered by PTFE coating.

The most commonly known PTFE materials brand is Teflon®, a DuPont brand. Also, there’s another PTFE coating material – Xylan®, a coating trademark produced by Whitford. Xylan® coating is designed and used for fasteners and components to offer superb corrosion resistance. EPI can offer both Teflon Coated Magnets and Xylan Coated Magnets.

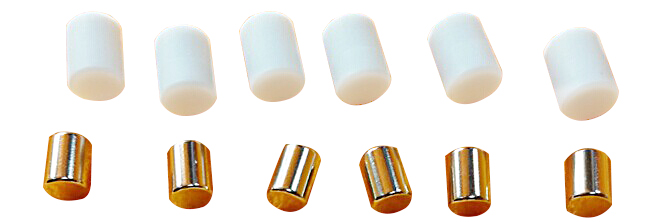

Teflon Coated Magnets:

High-performance Teflon coating materials EPI used are purchased from DuPont.

It should be noted that the thickness of Teflon coating is around 4 mm. Thick coating provides unimaginable corrosion resistant performance, which makes the magnets could be used in strong acid/ alkali environments. While, thick Teflon coating restricts the dimensions of the inner magnets and reduces the pull force and other magnetic performances.

For example, if the final product dimensions are 20 mm dia. x 18 mm thickness, the net dimensions of the inner magnets are 12 mm dia. x 10 mm thickness.

Please take this into consideration in the design and RFQ stages. You can Contact us or send us an email via Sales@epimagnets.com to send your RFQ or drawings.

If the reduction of the magnetic performance is not acceptable, we highly recommend choosing Xylan coated Magnets which have only 20~30 microns thickness coating.

Xylan Coated Magnets:

High-performance Xylan coating materials EPI offered are purchased from Whitford.

The most common grade of Xylan coating from EPI is Xylan 1424. The thickness is only 20~30 microns and the salt spray test(SST) result is 300-400 hours (While the SST result of NiCuNi coating is 72 hours).

EPI also provides double Xylan coatings to increase the corrosion resistance:

You can contact us by clicking the “Get A Quote” button or directly send your RFQ to sales@epimagnets.com.

We will contact you within 1 working day. You can also contact us by sending emails directly to sales@epimagnets.com.