Magnetic Materials: A Brief Overview

Magnetic materials are generally categorized into two groups: isotropic magnets and anisotropic magnets.

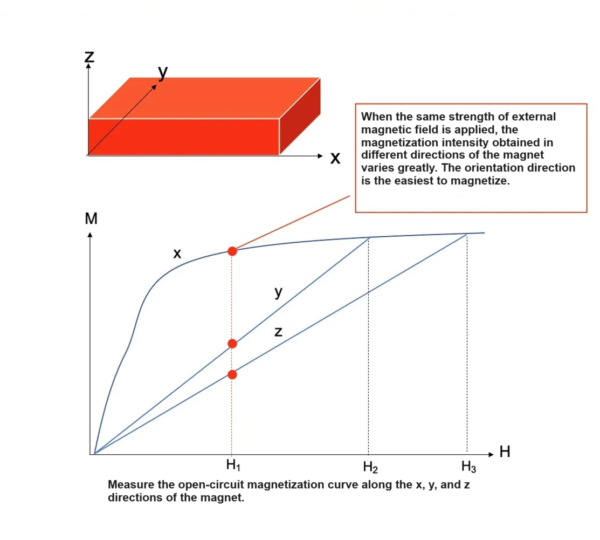

Isotropic Magnets: These magnets exhibit identical magnetic properties in every direction, allowing them to be magnetized in any orientation. This characteristic grants them a level of versatility, making them suitable for a variety of applications where a specific magnetic orientation is not a prerequisite.

Anisotropic Magnets: On the other hand, anisotropic magnets display different magnetic properties depending on the direction. The direction in which these magnets can achieve the best magnetic performance is known as the orientation direction. Sintered Neodymium (NdFeB) and sintered Samarium Cobalt (SmCo) are common examples of hard magnetic materials that fall under this category.

The Orientation Process: A Key Step in Manufacturing

The orientation process is a critical phase in the production of sintered Neodymium (NdFeB) magnets, a procedure that lays the foundation for the magnet’s inherent magnetic properties. The magnetism of these materials stems from magnetic ordering, where individual magnetic domains are systematically aligned in a specific direction. This alignment is achieved through a meticulous process where magnetic powder is compressed into a mold to form a specific shape.

At the onset of this process, the magnetic powder is placed into a mold which is then shaped under the influence of a strong magnetic field applied through an electromagnet. Simultaneously, a pressing machine exerts a certain amount of pressure on the magnetic powder, ensuring the easy magnetization axes of the particles are uniformly aligned. This step is crucial as it facilitates the creation of a magnet with optimal magnetic properties.

Once the pressing is completed, the blank undergoes a demagnetization process to remove any residual magnetism, followed by the removal from the mold. This results in a well-oriented blank that exhibits excellent magnetization directionality. Subsequently, based on the specific requirements of the users, this blank is cut into specified dimensions to create the final magnet product.

Powder orientation stands as a pivotal technique in the fabrication of high-performance Neodymium (NdFeB) permanent magnets. The quality of orientation during the blank production stage is influenced by a multitude of factors including the strength of the orientation magnetic field, the shape and size of the powder particles, the method of forming, the relative direction of the orientation field and forming pressure, and the loose packing density of the orientation powder, among others.

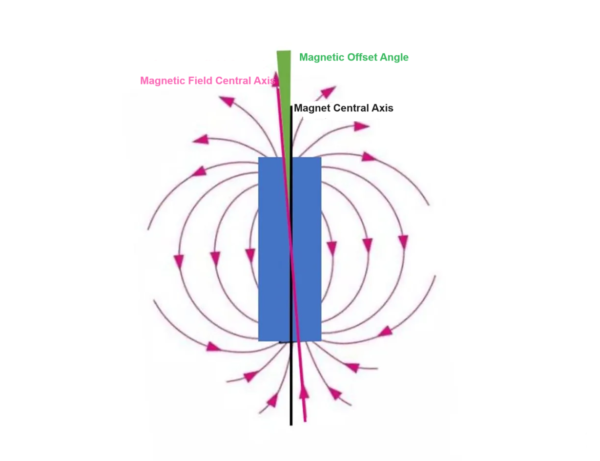

Furthermore, it is important to note that the magnetic offset angle generated during the post-processing stage can have a significant impact on the magnetic field distribution of the magnet steel, affecting the overall performance and efficiency of the final product.

Magnetization: The Final Phase

Magnetization stands as the final yet pivotal step in bestowing magnetic properties to sintered Neodymium (NdFeB) magnets. This phase encapsulates a series of processes that transform the magnet blank into a product that exhibits external magnetism, ready to be utilized in various applications.

After the magnet blanks are cut to the desired dimensions as per user requirements, they undergo anti-corrosion treatments such as electroplating to become finished magnet steel products. Despite these advancements, the magnet does not yet display any external magnetism. It necessitates a process called magnetization, or “charging,” to endow the magnet with its magnetic properties.

The equipment utilized for magnetizing the magnet steel is known as a magnetizer or a magnetizing machine. This machine operates by first charging its capacitors with a high direct current voltage, essentially storing energy. Following this, a discharge occurs through a coil with very low resistance, known as the magnetizing fixture. This discharge generates a pulse current with a peak that can reach tens of thousands of amperes, creating a potent magnetic field within the fixture. This magnetic field is capable of permanently magnetizing the magnet placed within the fixture, marking the culmination of the magnet’s manufacturing process.

However, the magnetization process is not devoid of challenges and potential mishaps. Instances of magnetization unsaturation, magnetizer pole head explosions, and magnet breakages are not uncommon. Unsaturated magnetization primarily occurs due to insufficient magnetization voltage.

In cases of multi-pole magnetization, magnets with a thicker orientation direction can be difficult to saturate fully. This is because the large gap between the upper and lower pole heads of the magnetizer produces an inadequate magnetic field strength, preventing the formation of a normal closed magnetic circuit. Consequently, the magnetic field cannot penetrate through the magnet, leading to pole confusion and insufficient magnetic field strength.

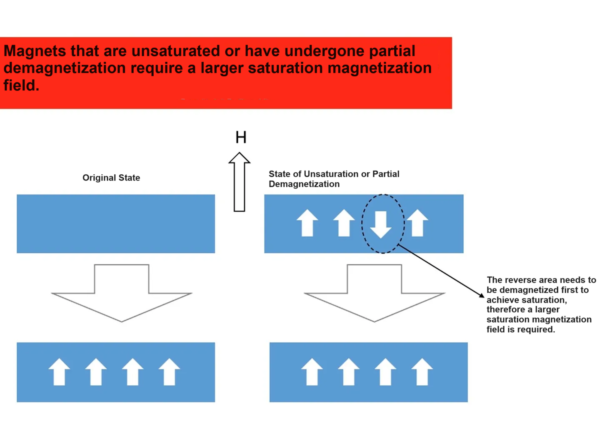

Magnetizer pole head explosions are typically the result of setting an excessively high voltage, surpassing the safe voltage levels of the magnetizing machine. Furthermore, magnets that are unsaturated or have undergone demagnetization but not completely cleaned are harder to saturate. Initially, the magnetic domains in these magnets are disordered, not displaying external magnetism. Achieving saturation requires overcoming the resistance of the displacement and rotation of their own magnetic domains. However, the presence of reverse magnetic field regions within these magnets necessitates a stronger magnetic field than theoretically calculated for successful magnetization, adding an extra layer of complexity to the process.