Introduction

Sintered neodymium-iron-boron (NdFeB) magnets, renowned for their exceptional magnetic properties, are primarily composed of neodymium (Nd), iron (Fe), and boron (B). However, the manufacturing process often incorporates several additional elements, each playing a unique role in enhancing the magnet’s performance. The formulation of these materials is a closely guarded secret among manufacturers, tailored to meet specific application requirements of their customers.

Just as various seasonings contribute to the flavor profile of a gourmet dish, the diverse elements within NdFeB magnets are scientifically combined based on their inherent characteristics and functionalities, leading to a wide range of grades and properties. Understanding the purpose of each element is crucial for comprehending the performance differences and manufacturing costs associated with different magnet grades.

Elemental Categories in Neodymium Magnets

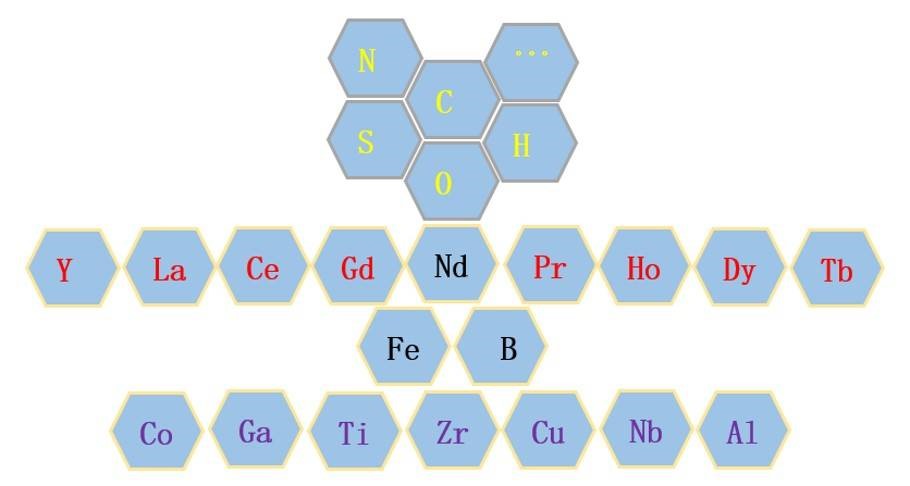

For ease of understanding, we can classify the elements in NdFeB magnets into three main categories:

- Primary Elements: These are the rare earth elements (RE), including cerium (Ce), gadolinium (Gd), neodymium (Nd), dysprosium (Dy), etc., along with iron (Fe) and boron (B). They are chiefly responsible for forming the RE2Fe14B main phase crystal grains.

- Minor Elements: Elements such as aluminum (Al), cobalt (Co), gallium (Ga), and zirconium (Zr) are tasked with optimizing the coverage of the grain boundary phase over the main phase crystal grains.

- Impurity Elements: Unavoidable in the sourcing of raw materials and production process, elements like carbon (C) and oxygen (O) are introduced as impurities.

The types of elements in a magnet are shown schematically below:

Quality Control and Material Selection

The production process involves rigorous inspection and treatment of raw materials to ensure optimal performance of the formulated magnets. Despite this, variations due to different manufacturing methodologies can lead to discrepancies in element ratios and concentrations. Adjustments based on batch-specific quality control reports are essential for maintaining desired magnet properties.

Common requirements for raw materials are shown in the table below:

Element | Common Purity or Ratio | Shape | Treatment Method |

Ce | >99% | Block | Remove oxide dust |

PrNd | >99% | Block | Remove oxide dust |

GdFe | 75% | Block | Remove oxide dust |

DyFe | 80% | Block | Remove oxide dust |

Tb | >99.9% | Block | Remove oxide dust |

HoFe | 80% | Block | Remove oxide dust |

Ga | >99.9% | Liquid | Freeze and package |

Al | >99.5% | Block/Rod | – |

Fe | >99.9% | Block/Rod | Shot blasting to remove paint and rust |

Co | >99.9% | Block/Flake | – |

BFe | 19-21% | Granules | Mix evenly |

Cu | >99.9% | Flake/Strand | – |

In practice, the typical reference values for common raw materials serve as a guide; actual values may vary significantly depending on the manufacturing process and the specific techniques employed. For instance, the ratio of PrNd can fluctuate from 20:80 to 25:75, the concentration of Gd in GdFe might drop below 75%, and the boron content in BFe can exhibit considerable variation between batches. Such deviations highlight the importance of adapting the blend of raw materials based on the actual contents documented in each batch’s quality inspection report.

These variations underscore the critical role of rigorous quality control measures and the need for flexible material selection strategies. By closely monitoring and adjusting for the specific characteristics of each batch of raw materials, manufacturers can ensure that the produced magnets not only meet but exceed performance expectations, thereby delivering optimal functionality and reliability in their applications.

Unique Characteristics of NdFeB Magnet Elements

- Cost-effective Solutions with La and Ce: Introducing La and Ce elements can reduce the magnet’s remanence (Br) and coercivity (Hcj) but are utilized to lower production costs.

- High-Performance Magnets with Nd: Utilizing pure neodymium enhances the magnet’s saturation magnetization, ideal for creating magnets with exceptionally high remanence.

- Enhancing Hcj with Tb: While significantly improving coercivity, terbium increases the cost substantially.

- Gd for High-Temperature Applications: Gadolinium forms REFeB with the highest Curie temperature, suitable for high-temperature magnets, albeit reducing Br to some extent.

To determine how to combine elements to manufacture magnets that meet specific performance requirements at the lowest cost, it’s crucial to understand the characteristics of each element within neodymium-iron-boron (NdFeB). Detailed characteristics of these elements are outlined in the following table.

Element | Density (g/cm³) | Melting Point (°C) | Material Cost | Effect on Br | Effect on Hcj | Adding Principle |

La | 6.16 | 920 | Very Low | Lower Br | Lower Hcj | Lower performance, lower cost |

Ce | 6.77 | 795 | Very Low | Lower Br | Lower Hcj | Lower performance, lower cost |

Gd | 7.9 | 1313 | Low | Lower Br | Lower Hcj | Lower performance, lower cost, high temperature resistance |

Pr | 6.77 | 931 | High | Lower Br | Increase Hcj | High Hcj |

Nd | 7 | 1024 | High | Increase Br | Lower Hcj | High Br |

Ho | 8.78 | 1470 | High | Lower Br | Increase Hcj | Increase Hcj |

Dy | 8.56 | 1409 | Very High | Lower Br | Increase Hcj | High Hcj |

Tb | 8.25 | 1356 | Extremely High | Lower Br | Increase Hcj | High Hc |

Co | 8.9 | 1495 | Low | Lower Br | – | Improve temperature coefficient |

Ga | 5.91 | 29.78 | Very High | Lower Br | Increase Hcj | Optimize grain boundary, increase Hcj |

Ti | 4.51 | 1668 | – (Small addition, minor cost impact) | Lower Br | Increase Hcj | Optimize grain boundary, increase Hcj |

Zr | 6.49 | 1852 | – (Small addition, minor cost impact) | Lower Br | Increase Hcj | Optimize grain boundary, increase Hcj |

Cu | 8.92 | 1085 | – (Small addition, minor cost impact) | Lower Br | Increase Hcj | Optimize grain boundary, increase Hcj |

Al | 2.7 | 660 | – (Small addition, minor cost impact) | Lower Br | Increase Hcj | Optimize grain boundary, increase Hcj |

Nb | 8.57 | 2468 | – (Small addition, minor cost impact) | Lower Br | Increase Hcj | Optimize grain boundary, increase Hcj |

B | 2.34 | 2076 | – (Small addition, minor cost impact) | Increase Br | Lower Hcj | Adjust proportion of main phase and grain boundary phase |

Fe | 7.86 | 1538 | – (Small addition, minor cost impact) | Increase Br | Lower Hcj | Become main phase |

C | 2.26 | 3500 | – | Lower Br | Lower Hcj | Impurity element |

O | 0.0014 | -218.79 | – | Lower Br | Lower Hcj | Impurity element |

S | 2.07 | 112.8 | – | Lower Br | – | Impurity element |

H | 0.00009 | -259.14 | – | Lower Br | – | Impurity element |

N | 0.0013 | -209.9 | – | Lower Br | Lower Hcj | Impurity element |

The Cost-Benefit Analysis in Magnet Production

Material costs, which constitute a significant portion of the overall expenses, are heavily influenced by the high or low cost of specific elements. Specifically, the material costs, accounting for 80%-90% or more of the total, are primarily comprised of the elements ranging from lanthanum (La) to gadolinium (Gd) as detailed in the aforementioned table. The inclusion of La and Ce aims at reducing costs without compromising quality significantly. With continuous advancements in production techniques, Ce-based magnets are finding their way into more sophisticated applications.

A thorough understanding of each element’s impact on the sintering process, density, aging treatments, and magnet performance is crucial for manufacturing NdFeB products that offer the best value for cost. This knowledge enables manufacturers to produce magnets that not only meet specific performance requirements but also do so in a cost-effective manner.

Conclusion

Understanding the intricate balance of elements in sintered neodymium-iron-boron (NdFeB) magnets is key to unlocking superior magnetic performance while managing production costs effectively. Each element, from lanthanum (La) to gadolinium (Gd), plays a pivotal role in determining the magnet’s properties, such as remanence and coercivity, impacting both the performance and cost. By strategically combining these elements, manufacturers can produce high-quality NdFeB magnets tailored to specific requirements. This guide offers a deep dive into the characteristics and cost implications of each constituent element, providing valuable insights for optimizing magnet production in terms of both functionality and affordability.