Have you ever wondered how to effectively mount an object to a vertical surface using magnets? Understanding the nuances of this can be a bit challenging, but here at EPI Magnets, we’ve simplified it into two key principles: leverage and friction. In this comprehensive guide, we aim to make this task easier for you, incorporating illustrative visuals for a better grasp of these concepts.

Leverage and Friction

The cornerstone of effectively using magnets to hold an object on a vertical surface such as a wall revolves around the correct understanding and application of leverage and friction.

Friction

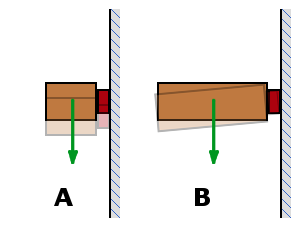

When you use a magnet to stick something to a steel wall, the magnet provides a force drawing towards the wall. However, it doesn’t counteract gravity’s downward pull. The key factor preventing the object from slipping down is friction. As seen in Picture A, the object may slide down when the gravitational force outweighs the friction between the magnet and the wall.

Predicting friction forces can be challenging, as we’ve discussed in our previous article, Understanding Magnetic Pull Force Your Ultimate Guide. This complexity arises from various factors, including the weight of the object, the type and smoothness of the surfaces in contact, and the angle at which the force is applied.

Leverage

Suppose the magnet maintains its grip and doesn’t slide. In that case, the weight of the object you’re holding can cause a rotational force, leading to the object peeling off the wall. The farther the object extends from the wall, the greater the leverage, causing the object to pry the magnets off the wall. Picture B illustrates this phenomenon, demonstrating how increased leverage could rotate the magnet off the wall.

Enhancing Friction

Adding friction can improve the grip of the magnet on the surface. One way to achieve this is by introducing a grippy material between the magnet and the steel surface. Options like our rubber-coated magnets or a layer of adhesive-backed polyurethane material can significantly increase the friction, reducing the likelihood of the object slipping down. However, increasing the distance between the magnet and the steel surface can slightly decrease the pull force. To give you a practical example, let’s look at the DC6-N52 disc magnet. This magnet exhibits a pull force of approximately 29.7 lb when placed against a steel plate. Now, if we compare it with a rubber-coated DC6TP-N52 magnet of the same exterior dimensions, we find that the latter has approximately half of the pull force. While it’s worth noting that the magnet encased within the rubber coating is smaller, it’s important to understand that the rubber coating may provide better resistance against sliding down a wall in certain applications, despite its lower pull force. In such scenarios, the increased friction provided by the rubber coating compensates for its decreased magnetic strength.

Battling Leverage

Objects that stick out from the wall more have higher leverage and may tend to pry the magnet off. A possible solution is to keep your object as close to the wall as possible, reducing its leverage.

Practical Scenarios: Shelves and Panels

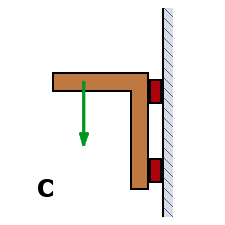

The Shelf: For a shelf attached to a steel surface using magnets, several strategies can enhance stability. The shelf should be as close to the wall as possible to limit leverage. Vertically separated magnets, as depicted in Picture C, provide more leverage and stability to the shelf.

The Panel: A common query we receive revolves around selecting the right magnets for supporting panels. These panels could be a hidden drawer in a piece of furniture, an access door under a spa, a wardrobe door, and so on. The objective, regardless of the specific application, is to secure a detachable panel using magnets.

The fundamental requirement here is that the magnets should possess sufficient strength to counteract the friction and leverage presented by the panel. The challenge arises when dealing with large and heavy panels akin to doors, which necessitate substantial magnetic strength to prevent them from sliding downwards. For instance, a lightweight panel weighing 5 lb might demand magnets having 30-40 lb of pull force to thwart it from slipping. If the intent of employing magnets is to facilitate easy removal of the panel, exerting 50 or 100 lb of force to achieve this is not exactly an intuitive approach! While we do provide magnets capable of exerting such high force, it’s understandable that nobody desires to apply over 100 pounds of force to disengage a 15-pound door.

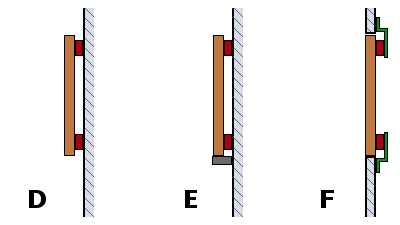

Generally, the most logical solution to the problem of sliding is a mechanical one. If the panel is positioned on some mechanical stop, as illustrated, the weight of the panel is borne by the stop rather than the magnets. This arrangement eliminates the reliance on friction to prevent the panel from sliding down.

In such situations, the necessary magnetic strength is only that which prevents the panel from tilting outward. The size and strength of the magnet are chosen to determine the force required for its removal. For instance, a standard refrigerator door requires around 5-10 lb of force to open, a specification we bear in mind when determining the appropriate size for such applications.

In Picture D, sufficient magnetic force and friction are needed to prevent the panel from sliding. However, in Pictures E and F, the panel is secured by a stop at the bottom, thereby negating the need for the magnets to support the entire weight of the panel.

Identifying the Ideal Magnet

The choice of the perfect magnet varies with the size, weight, and shape of the object you aim to hold. Our Countersunk Magnets and Mounting Magnets are popular choices for a wide variety of applications.

By dividing the object’s weight by a friction coefficient of 0.15, you can roughly estimate the required magnetic pull force. For instance, a 10 lb panel would need a total pull force of approximately 67 lb.

At EPI Magnets, we stand ready to assist you with your specific application. Don’t hesitate to contact our team for guidance and remember: experimenting with different magnets and setups will lead you to the best solution for your project.

We hope you found this comprehensive guide insightful. Understanding the interplay of friction and leverage is crucial when it comes to effectively using magnets to hold objects against vertical surfaces. Your unique project could benefit from the practical strategies and tips outlined in this article. Remember, your choice of magnet will depend on the specifics of your object and setup. Experimenting is key, and don’t hesitate to reach out for expert advice.

Keep exploring the world of magnets, and stay tuned to EPI Magnets for more exciting magnetic solutions!