As the quest for sustainable development presses on, the traditional vapor-compression refrigeration technology faces increased scrutiny over its environmental impact and energy efficiency. The emergence of magnetocaloric refrigeration, a solid-state cooling method based on the magnetocaloric effect, offers a promising alternative. This technology, operating without greenhouse gas emissions, ozone-depleting substances, and with the added benefits of low noise and vibration, stands at the forefront of potential next-generation refrigeration solutions.

Magnetocaloric Effect Explained

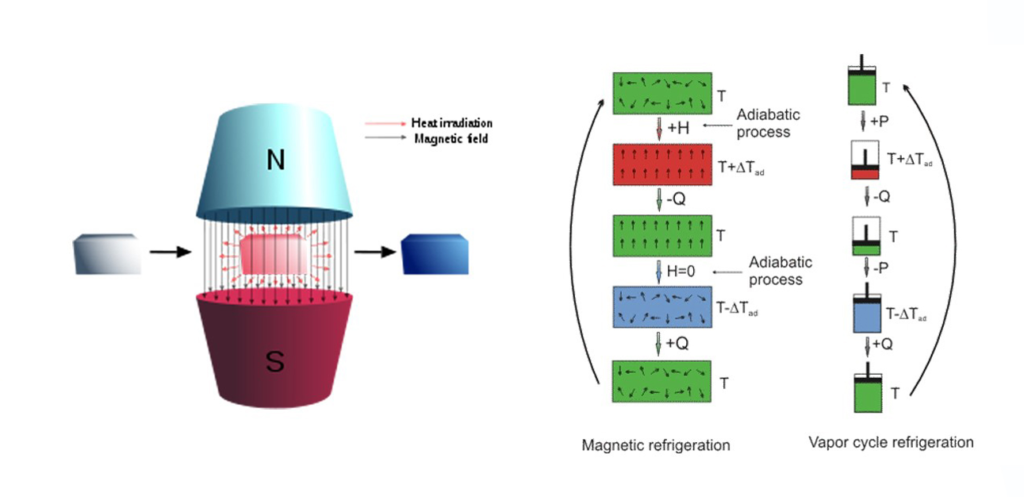

The magnetocaloric effect is a thermal phenomenon observed in magnetic materials due to changes in the order of their magnetic moments. When a magnetic material is magnetized, the order of the magnetic moments increases, the magnetic entropy decreases, and the temperature rises, releasing heat to the surroundings. Conversely, when the material is demagnetized, the order of the magnetic moments decreases, the magnetic entropy increases, and the temperature falls, absorbing heat from the environment.

This effect is at the heart of magnetic refrigeration and represents a significant advancement over traditional refrigeration techniques. By harnessing the properties of certain magnetic materials that heat up when magnetized and cool down when removed from the magnetic field, this eco-friendly technology can potentially reduce reliance on harmful refrigerants. The utilization of the magnetocaloric effect is a pivotal step towards more energy-efficient and environmentally responsible cooling systems.

Design of Magnetic Refrigeration Prototypes

Magnetic refrigeration prototypes are comprised of several subsystems, including a magnetic circuit system that generates a varying magnetic field, a regenerator system where the magnetocaloric effect occurs, and a fluid circuit system for heat transfer. Depending on the movement of the magnet and the changes in the magnetic field, these prototypes can be categorized as static, reciprocating, or rotating. The static type, which used to rely on costly and complex superconducting magnets, has been phased out. Nowadays, permanent magnets supply the magnetic field in most magnetocaloric refrigeration systems at room temperature.

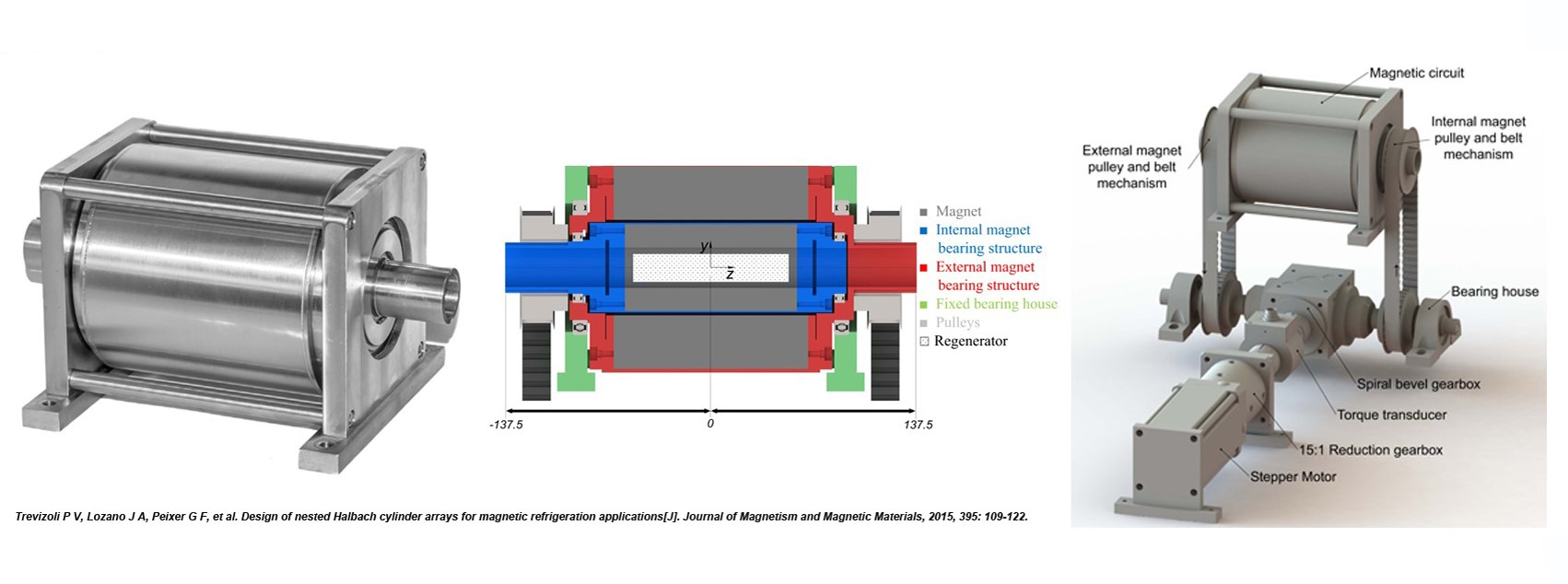

The magnetic circuit and regenerator systems are the core components of a room temperature magnetic refrigeration prototype. Based on the different operational modes of these components, the prototypes can be divided into systems with moving magnets or moving regenerators. Further distinctions are made according to the specific motion involved, resulting in four types: reciprocating-magnet, reciprocating-regenerator, rotating-magnet, and rotating-regenerator. Among these, the rotating-magnet type requires the use of a Halbach array.

Due to the difficulty in increasing the operating frequency of room temperature magnetic refrigeration systems with reciprocating magnets/regenerators, rotating magnet systems have become a key research focus. Recently, a significant proportion of these systems have emerged, notably from the University of Victoria in Canada, the Technical University of Denmark, the University of Salerno in Italy, and the NASA Technology Center in the United States.

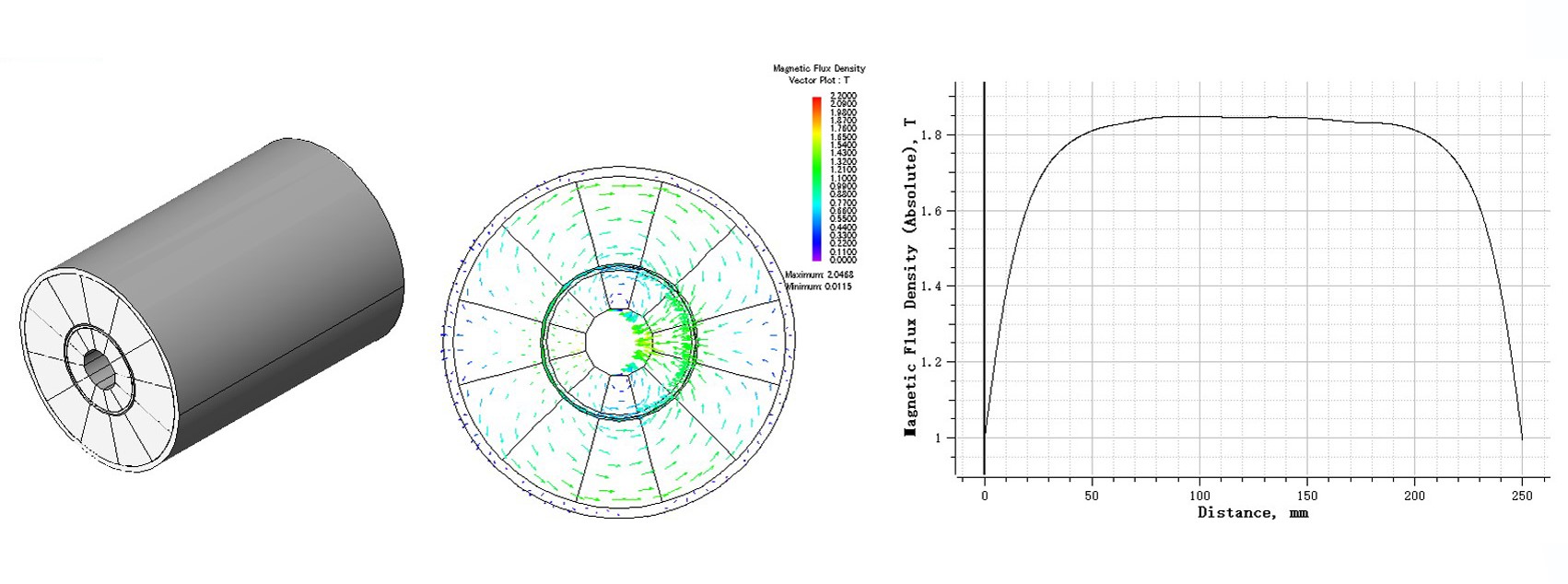

The University of Victoria, led by Arnold in 2014, showcased an improved prototype featuring a three-layer concentric nested Halbach permanent magnet assembly generating an alternating magnetic field. Each cylindrical nested magnet is composed of 12 segments. The innermost magnet assembly, producing half the magnetic field strength, remains stationary, while the outermost and middle layers, each generating a quarter of the magnetic field strength, rotate in opposite directions. This results in a sinusoidal magnetic field ranging from 0.29 to 1.54 T at the center, with a constant direction.

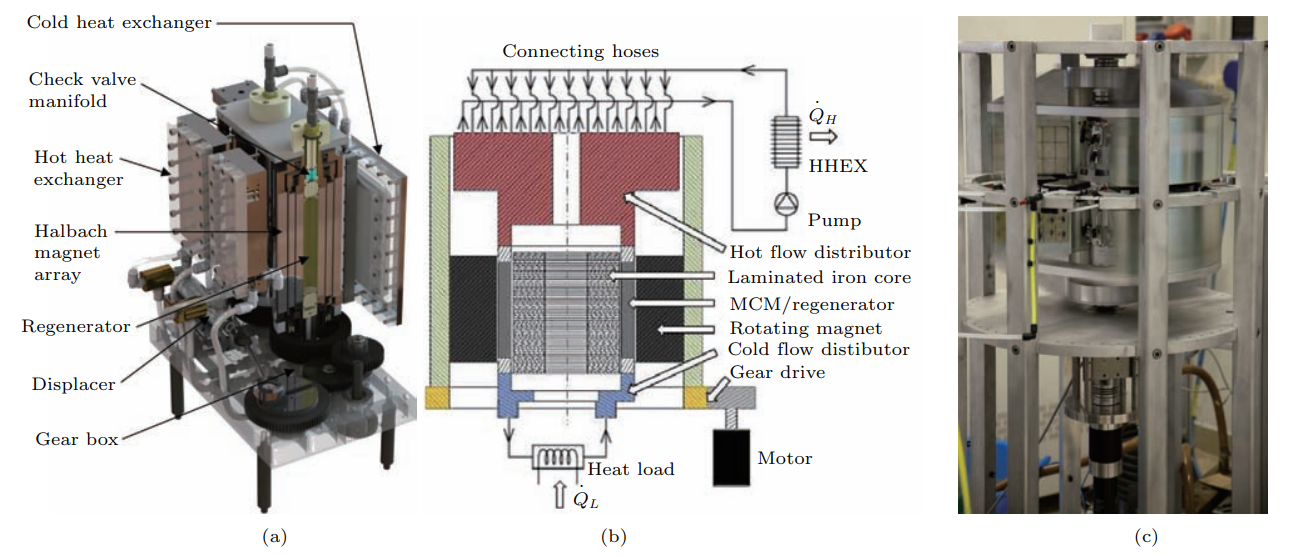

(a) Rotary-magnet magnetic refrigerator presented by Arnold in Canada

(b) Rotary-magnet magnetic refrigerator constructed by Eriksen in Denmark

(c) Rotary-magnet magnetic refrigerator built by Ghahremani in Italy

The Technical University of Denmark’s latest prototype aims to minimize the clearance effect of the heat transfer fluid, using check valves at both ends of the regenerator to direct fluid flow unidirectionally. The system uses 1.7 kg of Gd and GdY alloy as magnetocaloric materials, achieving a 10 K temperature span and a cooling capacity of 103 W at an operational frequency of 0.3 Hz, marking the highest reported second-law efficiency of 11.3%.

In 2016, Ghahremani and colleagues at the University of Salerno improved upon the rotating magnet prototype by filling eight regenerators with 1.2 kg of gadolinium spheres, measuring 0.4 to 0.5 mm in diameter. Operating at a magnetic field strength of 1.25 T and a fluid flow rate of 6.0 L/min, the system achieved an unloaded temperature span of 11.9 K and a cooling capacity of 200 W at zero temperature span.

To date, Jacobs and others at the NASA Technology Center have built the prototype system with the largest cooling capacity, using a rotating magnet structure. The system utilizes six layers of LaFeSiH alloy with different Curie temperatures as the filler for twelve annular regenerators, weighing a total of 1.52 kg. At a working frequency of 4 Hz, it achieves a maximum cooling capacity of 3042 W.

Compared to reciprocating magnet prototypes, rotating magnet room temperature magnetic refrigeration systems do not require a push-pull space, resulting in a more compact system structure and an easier increase in operating frequency. However, the use of a Halbach magnetic circuit results in lower magnet utilization, and similar to reciprocating magnet systems, the heavy magnet mass necessitates a high torque requirement for the drive motor during startup processes.

Advancements in Magnetic Refrigeration

EPI Magnets leverages the distinctive configuration of Halbach arrays to revolutionize magnetic refrigeration systems. The unique spatial arrangement of magnets in a Halbach array amplifies the magnetic field on one side of the array while canceling it on the other, resulting in a powerful and directed magnetic force. This arrangement not only facilitates a more compact design but also enhances the efficiency and consistency of the cooling process. EPI Magnets’ expertise in magnetic field simulation is instrumental for clients seeking to optimize their magnetic refrigeration solutions. By providing advanced simulation services, EPI Magnets enables clients to predict and enhance the performance of their refrigeration systems, ensuring a reliable and effective application in various industries.